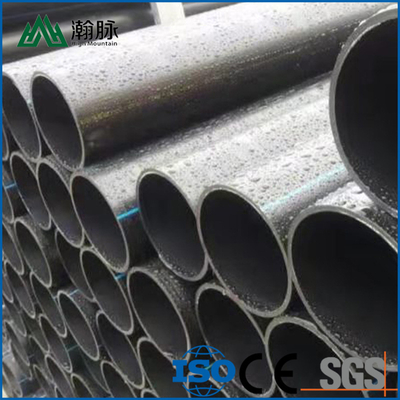

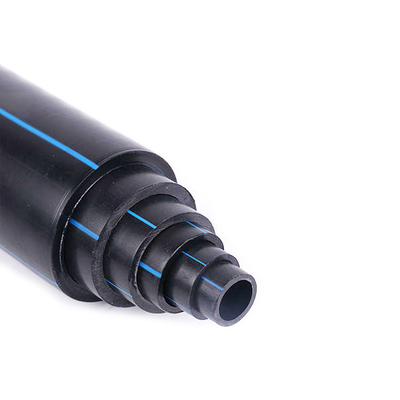

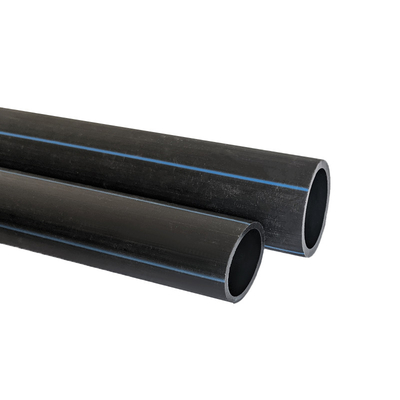

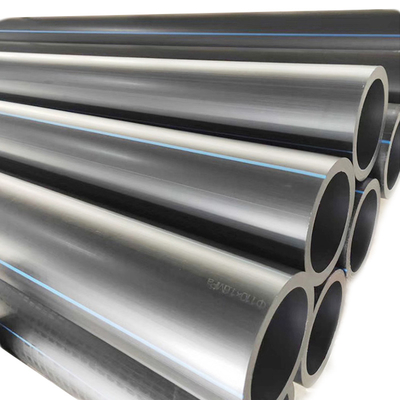

HDPE Pipe Garden Irrigation Agriculture Pipe PE Water Supply And Drainage Pipe

----------------------------------------

Basic Info.

HDPE water supply pipe and HDPE drainage pipe are both made of high-density polyethylene (HDPE), but they serve different purposes. HDPE water supply pipe is typically used to transport potable water to homes and businesses, while HDPE drainage pipe is usually used to carry wastewater away from a structure.

| Diameter(mm) |

Outer diameter(mm) |

Wall thickness

(mm) |

Weight/m

(kg) |

Weight/root(kg) |

Root/km |

Weight/km(ton) |

| 80 |

98 |

6 |

12.2 |

76.5 |

167 |

12.77 |

| 100 |

118 |

6.1 |

15.1 |

95 |

167 |

15.87 |

| 150 |

170 |

6.3 |

22.8 |

144 |

167 |

20.05 |

| 200 |

220 |

6.4 |

30.6 |

194 |

167 |

32.4 |

| 250 |

274 |

6.8 |

40.2 |

255 |

167 |

42.59 |

| 300 |

326 |

7.2 |

50.8 |

323 |

167 |

53.94 |

| 350 |

378 |

7.7 |

63.2 |

403 |

167 |

67.3 |

| 400 |

429 |

8.1 |

75.5 |

482 |

167 |

80.48 |

| 450 |

480 |

8.6 |

89.3 |

575 |

167 |

95.86 |

| 500 |

532 |

9 |

104.3 |

669 |

167 |

111.72 |

| 600 |

635 |

9.9 |

137.3 |

882 |

167 |

147.29 |

| 700 |

738 |

10.8 |

173.9 |

1123 |

167 |

187.54 |

| 800 |

842 |

11.7 |

215.2 |

1394 |

167 |

232.8 |

| 900 |

945 |

12.6 |

260.2 |

1691 |

167 |

282.4 |

| 1000 |

1048 |

13.5 |

309.3 |

2017 |

167 |

336.84 |

| 1200 |

1255 |

15.3 |

420.1 |

2758 |

167 |

460.69 |

Advantage

The main features of HDPE pipes are: good toughness and flexibility; small friction coefficient and strong passing ability; convenient construction, good chemical stability, long service life, suitable deflection, good resistance to rapid crack transmission, resistance to Low temperature, conform to the requirements of the times, "green" environmental protection.

Details

Application

1. Municipal engineering water supply system

2. Building indoor water supply system

3. Outdoor buried water supply system and residential area

4. Buried water supply system in the plant

5. Old pipeline repair

6. Water treatment engineering piping system

7. Industrial water pipes in gardens, irrigation and other fields.

Certificate

Company Profile

Our company's products are of high quality, and we always adhere to and implement the quality policy of "Quality is the foundation of a company's survival, and providing users with satisfactory products and services is our eternal pursuit". . Our company is a factory direct sale of ductile iron pipes, ductile iron pipe fittings, ductile iron manhole covers, Xinxing ductile pipes, ductile iron well grate; W type flexible cast iron pipe, W type cast iron drainage pipe and pipe fittings; A type flexible cast iron pipe, A type cast iron drainage Pipes and fittings, B-type flexible cast iron pipes, B-type cast iron drainage pipes and pipe fittings and other products. Our company is a group company integrating production and sales. The annual production capacity of ductile iron pipes and flexible drainage pipes is 300,000 tons; the annual sales volume of ductile iron pipes is 120,000 tons and the annual sales volume of flexible drainage pipes is 180,000 tons.

FAQ

Q: What is the delivery time?

A: We always have common products in stock and can be shipped within 30 days.

Large orders require 15 days to complete production.

Q: Why choose us?

A: We are a professional manufacturer with competitive price, excellent quality and fast delivery time.

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!