4 HDPE Water Pipes Black PE Culvert Pipes For Drainage Projects Support Customization

----------------------------------------

Basic Info.

HDPE pipes come in various sizes, ranging from small diameters suitable for residential plumbing to larger diameters used in municipal water supply, irrigation, industrial applications, and more. The availability of different classes, such as DR11, enables engineers and contractors to select pipes based on the specific pressure requirements of their projects.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

Corrosion resistance: PE water pipes are made of high-density polyethylene, which has excellent corrosion resistance and can resist the erosion of various chemical substances.

Pressure resistance: PE water pipes have excellent pressure resistance and can withstand water flow under high pressure, ensuring the safety of water supply and transportation.

Lightweight and high strength: PE water pipes are light in weight, high in strength, easy to transport and install, not easy to be damaged, and have a long service life.

Environmental protection and health: PE water pipes meet environmental protection standards, do not contain any harmful substances, and are harmless to human health.

Details

Application

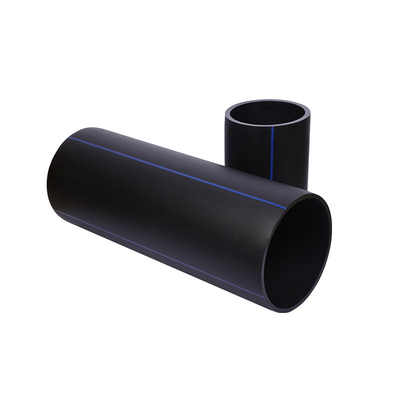

Mining: In the mining industry, HDPE pipes are used for transporting slurry, tailings, and other mining fluids. Their durability and resistance to abrasion make them suitable for harsh mining environments.

Industrial Applications: HDPE pipes serve various industrial purposes, including the transport of chemicals, acids, and other corrosive substances. Their chemical resistance and high strength make them suitable for a range of industrial processes.

Stormwater Management: HDPE pipes are employed in stormwater drainage systems due to their ability to handle high-volume water flow, resistance to abrasion, and durability in underground installations.

Certificate

Company Profile

High Mountain Pipe is a company specializing in the production of hdpe double-wall corrugated pipes, plastic corrugated pipes, hdpe drainage pipes, HDPE-enhanced double-wall hollow winding pipes, HDPE-enhanced double-wall socket flared hollow winding pipes, HDPE double-wall corrugated pipes, hollow bi-well pipes, HDPE An enterprise that winds structure wall B type pipe (carat pipe), HDPE wind structure wall C type pipe (carat pipe), and inner rib reinforced polyethylene spiral corrugated pipe. The company has 61 fully automated production equipment (large-caliber production lines) of advanced technology in the industry, and two imported testing equipment laboratories. It implements a strict quality control system to ensure the quality of products from raw materials to finished products. The product has been tested by the National Chemical Building Materials Testing Center, and the performance indicators of B and C pipes are in compliance with the GB/T19472.2-2017 standard. It has passed the China Environmental Protection Mark certification and won the 1S09001-2015 quality system certification.

FAQ

Q: How and when can I receive my goods after payment?

A: For small batch products, they will be delivered to you by international express (DHL, FedEx, TNT, etc.) or by air. It usually takes 3-5 days to receive the goods after delivery. For high-volume products, it is worthwhile to see the goods and deliver them. It takes several days to several weeks to reach the destination port, depending on the location of the port.

Q: How do you guarantee that the products you provide are qualified?

A: We always believe that integrity and responsibility are the foundation of a company, so any products we provide you are qualified. We will test the goods and provide COA before delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!