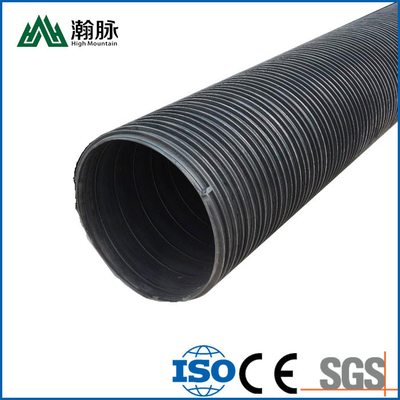

HDPE Double Wall Corrugated Pipe 300 400 500 600 800 Double Arm Corrugated Pipe Municipal Sewage Pipes

----------------------------------------

Basic Info.

HDPE drainage pipes are based on high-density polyethylene resin and are collectively referred to as thermoplastic round pipes without internal pressure, which are made by extrusion molding process.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

Good hygiene performance:

No heavy metal salt is added during PE pipe processing, the material is non-toxic, no scaling layer, no bacteria breeding, and it solves the city well.

Secondary pollution of drinking water. Excellent corrosion resistance: good impact resistance: reliable connection performance: long service life: flexibility:

Except for a few oxidants, it is resistant to a variety of chemical media and has no electrochemical corrosion.

The PE pipe has good toughness and high impact resistance, and the heavy objects are directly pressed through the pipe, which will not cause the pipe to rupture.

The welding process is simple; the unique hot-melt butt welding technology makes the interface strength higher than the strength of the pipe body, ensuring the safety and reliability of the interface.

Under rated temperature and pressure, PE pipe can be used safely for more than 50 years.

The elongation at break of the PE pipe is more than 350%, the impact resistance is high, and the strong earthquake and distortion are resistant. Under different ground subsidence and earthquakes, the crust changes

The pipe will not be broken and has high safety.

Cold resistance: workability: abrasion resistance:

There will be no physical changes even at -40C°, which is especially suitable for severe cold areas.

The PE pipe is light in weight (only 1/8 of the steel pipe). It is convenient to transport and construct, and the overall project cost is low. The smooth inner wall has a low coefficient of friction, and the media passing capacity is correspondingly improved and has excellent wear resistance.

Details

Application

It is suitable for urban tap water system whose temperature does not exceed 40℃; rural drinking water system; building water system; sewage treatment and transportation; chemical industry and other fields.

Certificate

Company Profile

High Mountain Pipe is a production enterprise focusing on core technology of pipelines.

The company introduced advanced production equipment and manufacturing technology, and successively developed grooved (HDPE) high-density polyethylene mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and high-density polyethylene siphon drainage system. Series products.

FAQ

Q: Is the price on this page correct?

A: The listed prices are for reference only, please contact us directly for the latest prices.

Q: What is the purpose of this pipeline?

A: It is mainly used to transport liquids, and is used on a large scale in urban water supply projects, farmland irrigation, etc.

Q: What certificates do you have for this product?

A: ISO, CE, SGS, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!