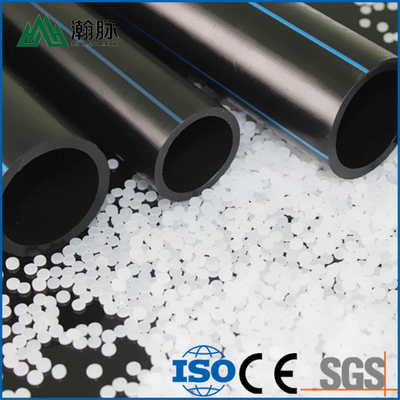

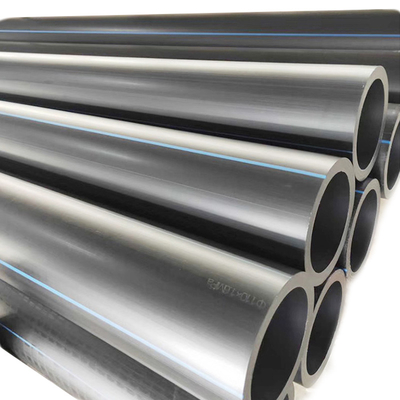

HDPE Water Supply Pipe Irrigation Agricultural Pipe Customized PE Pipe

----------------------------------------

Basic Info.

PE pipes for water supply are the replacement products of traditional steel pipes and PVC drinking water pipes.The water supply pipe must bear a certain pressure, usually a PE resin with a large molecular weight and good mechanical properties, such as HDPE resin, should be used. LDPE resin has low tensile strength, differential pressure resistance, poor rigidity, poor dimensional stability during molding and difficult connection, and is not suitable as a material for water supply pressure pipes. However, due to its high hygienic index, LDPE, especially LLDPE resin, has become a common material for the production of drinking water pipes. LDPE and LLDPE resins have low melt viscosity, good fluidity, and easy processing, so their melt index can be selected in a wide range, usually MI is between 0.3-3g/10min.

| Diameter(mm) |

Outer diameter(mm) |

Wall thickness

(mm) |

Weight/m

(kg) |

Weight/root(kg) |

Root/km |

Weight/km(ton) |

| 80 |

98 |

6 |

12.2 |

76.5 |

167 |

12.77 |

| 100 |

118 |

6.1 |

15.1 |

95 |

167 |

15.87 |

| 150 |

170 |

6.3 |

22.8 |

144 |

167 |

20.05 |

| 200 |

220 |

6.4 |

30.6 |

194 |

167 |

32.4 |

| 250 |

274 |

6.8 |

40.2 |

255 |

167 |

42.59 |

| 300 |

326 |

7.2 |

50.8 |

323 |

167 |

53.94 |

| 350 |

378 |

7.7 |

63.2 |

403 |

167 |

67.3 |

| 400 |

429 |

8.1 |

75.5 |

482 |

167 |

80.48 |

| 450 |

480 |

8.6 |

89.3 |

575 |

167 |

95.86 |

| 500 |

532 |

9 |

104.3 |

669 |

167 |

111.72 |

| 600 |

635 |

9.9 |

137.3 |

882 |

167 |

147.29 |

| 700 |

738 |

10.8 |

173.9 |

1123 |

167 |

187.54 |

| 800 |

842 |

11.7 |

215.2 |

1394 |

167 |

232.8 |

| 900 |

945 |

12.6 |

260.2 |

1691 |

167 |

282.4 |

| 1000 |

1048 |

13.5 |

309.3 |

2017 |

167 |

336.84 |

| 1200 |

1255 |

15.3 |

420.1 |

2758 |

167 |

460.69 |

Advantage

1. Excellent corrosion resistance, better hygiene performance and longer service life

2. Unique flexibility and excellent scratch resistance

3. Very outstanding low temperature resistance

4. Good fracture toughness with rapid crack growth

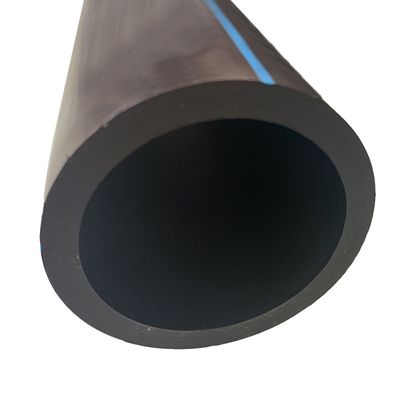

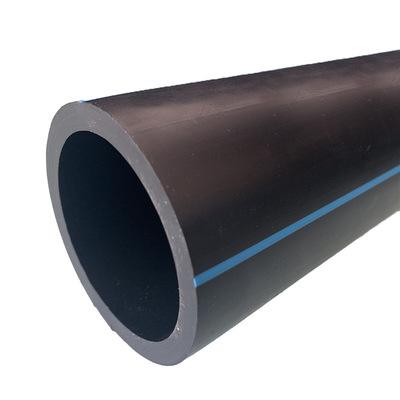

Details

Application

1. A variety of non-excavation methods can be used, and the construction and installation are extremely convenient.

2. The system cost is low, and the maintenance cost is low, which can greatly reduce the project cost.

3. No leakage: PE pipe adopts electrofusion connection, and its interface strength is higher than the pipe itself.

4. High toughness: The elongation at break of PE pipe is generally above 500%.For the uneven settlement of the base layer, its adaptability is very strong and the seismic performance is good.

5. Excellent resistance to rapid crack propagation (RCP).

6. Excellent flexibility and scratch resistance.

7. Good wear resistance, low wall friction coefficient, low flow resistance, and excellent conveying capacity.

Certificate

Company Profile

Our company's products are of high quality, and we always adhere to and implement the quality policy of "Quality is the foundation of a company's survival, and providing users with satisfactory products and services is our eternal pursuit". . Our company is a factory direct sale of ductile iron pipes, ductile iron pipe fittings, ductile iron manhole covers, Xinxing ductile pipes, ductile iron well grate; W type flexible cast iron pipe, W type cast iron drainage pipe and pipe fittings; A type flexible cast iron pipe, A type cast iron drainage Pipes and fittings, B-type flexible cast iron pipes, B-type cast iron drainage pipes and pipe fittings and other products. Our company is a group company integrating production and sales. The annual production capacity of ductile iron pipes and flexible drainage pipes is 300,000 tons; the annual sales volume of ductile iron pipes is 120,000 tons and the annual sales volume of flexible drainage pipes is 180,000 tons.

FAQ

Q: How do you guarantee that the products you provide are qualified?

A: We always believe that integrity and responsibility are the foundation of a company, so any products we provide you are qualified. We will test the goods and provide COA before delivery.

Q: Can you make special designs and logos on your products?

A: Yes, it is very easy.

Q: Can I customize the size I need?

A: Yes

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!