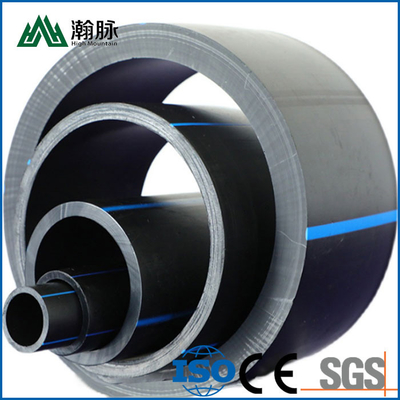

20mm 25mm 32mm 40mm 50mm 63mm HDPE Pipe For Water Supply And Drainage

----------------------------------------

Basic Info.

Can HDPE Pipe Be Used for Hot Water?

HDPE pipes exhibit excellent thermal properties, making them suitable for a wide range of temperatures. They can handle both cold and hot water, adding to their versatility in water distribution systems. The material remains robust and resilient even when exposed to elevated temperatures, making HDPE pipes a reliable choice for transporting hot water.

The thermal properties of HDPE pipes make them particularly advantageous in applications where the temperature of the transported water fluctuates. Whether it's for residential plumbing systems or industrial processes requiring hot water, HDPE pipes offer a dependable solution.

| Size |

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 20 |

2.3 |

2.3 |

|

|

|

|

| 25 |

3.0 |

2.3 |

2.3 |

|

|

|

| 32 |

3.6 |

3.0 |

2.4 |

|

|

|

| 40 |

4.5 |

3.7 |

3.0 |

2.4 |

|

|

| 50 |

5.6 |

4.6 |

3.7 |

3.0 |

|

|

| 63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 110 |

12.3 |

10.0 |

8.1 |

6.6 |

5.3 |

4.2 |

| 125 |

14.0 |

11.4 |

9.2 |

7.4 |

6.0 |

4.8 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15.0 |

12.1 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30.0 |

24.1 |

| 710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

Good hygienic performance: no heavy metal salt stabilizer is added during the processing of PE pipe, the material is non-toxic, no scaling layer, no bacteria breeding,

A good solution to the secondary pollution of urban drinking water.

Excellent corrosion resistance: Except for a few strong oxidants, it can resist the erosion of various chemical media; no electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years under rated temperature and pressure conditions.

Good impact resistance: PE pipe has good toughness and high impact resistance, and heavy objects directly press through the pipeline, which will not cause the pipeline to break violently.

Details

Application

Urban water pipe network system

Replaceable cement, cast iron and steel pipes

Industrial raw material pipeline

Landscaping water supply network

Pipes for sewage discharge

agricultural irrigation pipes

marine pipeline

Seawater desalination pipeline

Certificate

Company Profile

High Mountain Pipe is a production enterprise focusing on core technology of pipelines.

The company introduced advanced production equipment and manufacturing technology, and successively developed grooved (HDPE) high-density polyethylene mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and high-density polyethylene siphon drainage system. Series products.

FAQ

Q: What are raw materials?

A: PE

Q: How to get free samples?

A: Send your address, telephone number, zip code and express account number to our mailbox, and tell us which model of samples you need. Our sales team will contact you within 24 hours.

Q: What is your minimum order quantity?

A: Accessories: one box or one bag.

Pipeline: 200~5000 meters/size, depending on different sizes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!