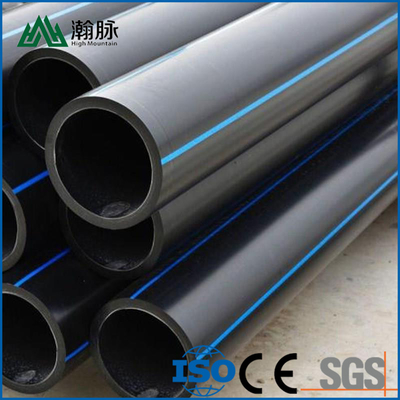

Manufacture Hdpe Pipe Various Black Pipe Pe Hdpe Water Drain Sewer Plastic Pipe

----------------------------------------

Basic Info.

Polyethylene PE water supply pipes are widely used in building water supply, building drainage, buried drainage pipes, building heating, gas transmission pipes, welding and telecommunications maintenance casings, industrial pipes, and agricultural pipes because of their unique advantages. Wait. Its key applications are urban water supply, urban gas supply, farmland irrigation and other industries. PE (polyethylene) raw materials are widely used in the water supply pipe manufacturing industry because of their high strength, corrosion resistance, and non-toxic properties; because it is not easy Rust, therefore, is an ideal pipe to replace ordinary iron water supply pipes.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

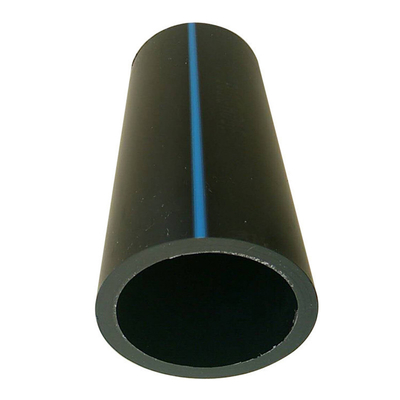

Long service life: PE pipes can be safely used for more than 50 years under rated temperature and pressure conditions.

Good impact resistance: PE pipe has good toughness and high impact resistance, and heavy objects directly press through the pipeline without causing the pipeline to rupture.

Reliable connection performance: The strength of the PE pipe hot-melt or electro-melt interface is higher than that of the pipe body, and the joint will not be disconnected due to soil movement or live load.

Good construction performance: the pipeline is light in weight, the welding process is simple, the construction is convenient, and the overall project cost is low.

Connection of pipes:

Electrothermal fusion: A special electric fusion welding machine is used to connect straight pipes to straight pipes and straight pipes to pipe fittings. Generally used for pipes below 160mm.

Hot-melt butt connection: use special butt welding machine to connect pipes, generally used for pipes above 160mm.

Steel-plastic connection: It can be connected by flange, screw thread and other methods.

In order to facilitate construction and ensure construction quality, corresponding tools should also be prepared.

Details

Application

1. Agricultural irrigation pipes: PE water supply pipes have smooth inner walls, large flow capacity, and good impact resistance. They are ideal pipes for agricultural irrigation;

2. Natural gas and coal gas pipelines: PE water supply pipes have good creep resistance and economy, and have become the only choice for natural gas pipelines;

3. Renovation of old pipes: it can be used to replace cement pipes, cast iron pipes and steel pipes, without large-scale excavation, and PE water supply pipes can be directly inserted, which is convenient for construction and low in engineering cost, especially suitable for pipeline transformation in old urban areas;

4. Landscaping pipe network: Landscaping requires a large number of water pipes. PE water supply pipes are flexible and low-cost, which is the best choice;

5. Sewage discharge pipe: PE water supply pipe has unique corrosion resistance and is suitable for the discharge of industrial wastewater and sewage. It not only has a long life, but also has low cost and maintenance costs;

6. Mine mortar transportation: PE water supply pipes have high-strength compression resistance, wear resistance and corrosion resistance, and can be used for ore transportation and mud transportation for river dredging.

Certificate

Company Profile

High Mountain Pipe Management Industry With 19 years of experience in R&D, production and sales of plastic pipe fittings, HDPE pipes are of good quality. In order to meet the actual needs of modern high-quality buildings and the design concept of environmental protection and silence, the company has introduced advanced production equipment and manufacturing technology, and has successively developed grooved ( HDPE) HDPE mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and HDPE siphon drainage system series products. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. hdpe pipe factory adheres to the factory policy of "credibility, quality and management as the fundamental goal", with moderate price, dedicated service, and customer satisfaction as the purpose, abiding by contracts and keeping promises and famous all over the country.

FAQ

Q: Can I customize the size I need?

A: Yes

Q: Which payment method can your company use?

A: T/T, L/C or full trade insurance. You can choose the one that is convenient for you.

Q: How and when can I receive my goods after payment?

A: For small batch products, they will be delivered to you by international express (DHL, FedEx, TNT, etc.) or by air. It usually takes 3-5 days to receive the goods after delivery. For high-volume products, it is worthwhile to see the goods and deliver them. It takes several days to several weeks to reach the destination port, depending on the location of the port.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!