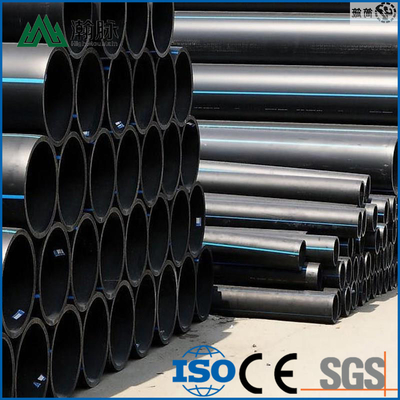

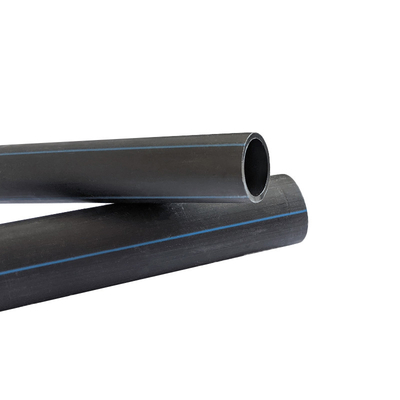

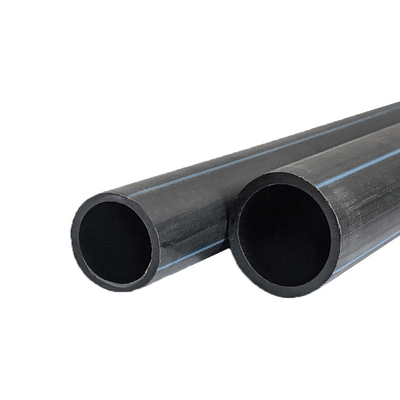

160mm HDPE Pipe High Durability And Strength Steel Wire Reinforced Hdpe Pipe

----------------------------------------

Basic Info.

The skeleton PE pipe is an improved new type of steel skeleton plastic composite pipe. This new type of pipeline is made of high-strength over-plastic steel mesh skeleton and thermoplastic polyethylene as raw materials, and steel mesh winding is used as the skeleton reinforcement feature of polyethylene plastic pipe. The bonding resin tightly connects the steel wire skeleton with the inner and outer layers of high-density polyethylene, so that it has excellent composite results. Because of the high strength steel wire reinforcement encased in the continuous thermoplastic, the composite pipe overcomes the respective disadvantages of the steel pipe and the plastic pipe, while maintaining the respective advantages of the steel pipe and the plastic pipe.

| SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

| Pressure 0.6Mpa |

Pressure 0.8Mpa |

Pressure 1.0Mpa |

Pressure 1.25Mpa |

Pressure 1.6Mpa |

| Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

| 110 |

4.2 |

90 |

4.3 |

75 |

4.5 |

63 |

4.7 |

20 |

2.3 |

| 125 |

4.8 |

110 |

5.3 |

90 |

5.4 |

75 |

5.6 |

25 |

2.3 |

| 140 |

5.4 |

125 |

6 |

110 |

6.6 |

90 |

6.7 |

32 |

3 |

| 160 |

6.2 |

140 |

6.7 |

125 |

7.4 |

110 |

8.1 |

40 |

3.7 |

| 180 |

6.9 |

160 |

7.7 |

140 |

8.3 |

125 |

9.2 |

50 |

4.6 |

| 200 |

7.7 |

180 |

8.6 |

160 |

9.5 |

140 |

10.3 |

63 |

5.8 |

| 225 |

8.6 |

200 |

9.6 |

180 |

10.7 |

160 |

10.8 |

75 |

6.8 |

| 250 |

9.6 |

225 |

10.8 |

200 |

11.9 |

180 |

13.3 |

90 |

8.2 |

| 280 |

10.7 |

250 |

11.9 |

225 |

13.4 |

200 |

14.7 |

110 |

10 |

| 315 |

12.1 |

280 |

13.4 |

250 |

14.8 |

225 |

16.6 |

125 |

11.4 |

| 355 |

13.6 |

315 |

15 |

280 |

16.6 |

250 |

18.4 |

140 |

12.7 |

| 400 |

15.3 |

355 |

16.9 |

315 |

18.7 |

280 |

20.6 |

160 |

14.6 |

| 450 |

17.2 |

400 |

19.1 |

355 |

21.1 |

315 |

23.2 |

180 |

16.4 |

| 500 |

19.1 |

450 |

21.5 |

400 |

23.7 |

355 |

26.1 |

200 |

18.2 |

| 560 |

21.4 |

500 |

23.9 |

450 |

26.7 |

400 |

29.4 |

225 |

20.5 |

| 630 |

24.1 |

560 |

26.7 |

500 |

29.7 |

450 |

33.1 |

250 |

22.7 |

| 710 |

27.2 |

630 |

30 |

560 |

33.2 |

500 |

36.8 |

280 |

25.4 |

| 800 |

30.6 |

710 |

33.9 |

630 |

37.4 |

560 |

41.2 |

315 |

28.6 |

| 900 |

34.4 |

800 |

38.1 |

710 |

42.1 |

630 |

46.3 |

355 |

32.2 |

| 1000 |

38.2 |

900 |

42.9 |

800 |

47.4 |

710 |

52.2 |

400 |

36.3 |

| 1200 |

45.9 |

1000 |

47.7 |

900 |

53.3 |

800 |

58.8 |

450 |

40.9 |

| |

|

1200 |

57.2 |

1000 |

59.3 |

|

|

500 |

45.4 |

| |

|

|

|

|

|

|

|

560 |

50.8 |

| |

|

|

|

|

|

|

|

630 |

57.3 |

Advantage

1. Thermal conductivity: pipes used for floor heating need to have good thermal conductivity. PE-RT has better thermal conductivity, and its thermal conductivity is twice that of PP-R and PP-B pipes. It is very suitable for floor heating.

2. High temperature resistance: The high temperature resistance of PE-RT can reach 90°C, while that of PEX can only reach 65°C.

3. Low temperature thermal shock resistance: PE-RT has better low temperature shock resistance. During winter construction, the pipes are not susceptible to impact and rupture, which increases the flexibility of construction arrangements.

4. Environmental protection: PE-RT and PP-R can be recycled and will not pollute the environment. The PEX cannot be recycled will cause secondary pollution.

5. Stability of processing performance: PEX has the problems of controlling the degree of cross-linking and cross-linking uniformity. The processing is complicated and the processing directly affects the performance of the pipe. However, PE-RT and PP-R are easy to process, and the performance of the pipe is basically determined by the raw material, and the performance is relatively stable.

Details

Application

Urban water pipe network system.

Urban and rural drinking water pipelines.

Material and liquid transportation pipelines in chemical, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, papermaking, metallurgy and other industries.

Agricultural irrigation pipes.

Posts and telecommunications lines, power wire protection casing.

Mine mortar pipeline.

Certificate

Company Profile

High Mountain Pipe is a high-tech enterprise integrating R&D, production and sales, specializing in the production of ultra-high molecular weight polyethylene pipes, tunnel escape pipes, steel belt reinforced polyethylene (HDPE) spiral corrugated pipes, HDPE pipes, inner and outer plastic coated composite steel pipes, 3PE A series of multi-specification pipe products such as anti-corrosion pipelines, gas station oil pipelines, oil well pipes, MPP power pipes, etc.

The company is equipped with a number of production lines of the same industry at home and abroad. The company always adheres to the concept of "innovation, efficiency, and integrity", absorbs new ideas, strictly controls quality, follows all-round services, and insists on making high-quality products. Adhering to the tenet of "pursuing and creating brilliance", we provide solid and reliable guarantee and support for customers' production and operation. Become a reliable partner for the majority of users. Product sales are exported to Brazil, the Philippines, Australia, the United States, Mexico, South Africa and other countries, and have won unanimous praise from customers! Survive by quality, develop by reputation, we warmly welcome your patronage and sincerely look forward to serving you!

FAQ

Q: How and when can I receive my goods after payment?

A: For small batch products, they will be delivered to you by international express (DHL, FedEx, TNT, etc.) or by air. It usually takes 3-5 days to receive the goods after delivery. For high-volume products, it is worthwhile to see the goods and deliver them. It takes several days to several weeks to reach the destination port, depending on the location of the port.

Q: Is it possible to use the label or packaging I specified?

A: Yes. If necessary, we would like to use labels or packaging according to your requirements.

Q: Which payment method can your company use?

A: T/T, L/C or full trade insurance. You can choose the one that is convenient for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!