High Quality 12 Inch Hdpe Pipe Prices PE Water And Irrigation Pipes Hdpe Tubes

----------------------------------------

Basic Info.

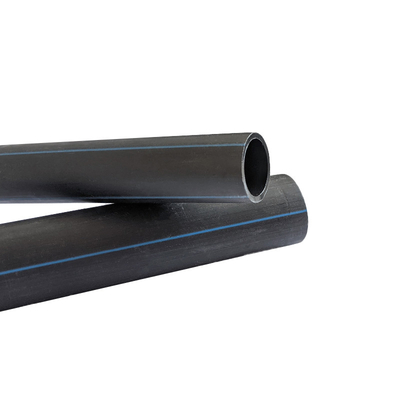

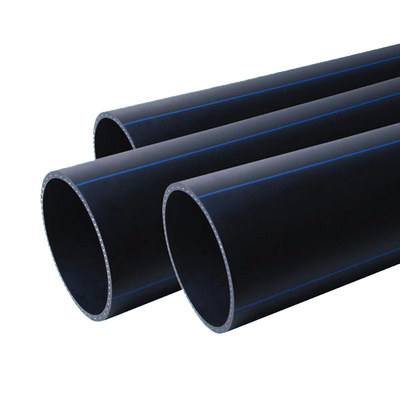

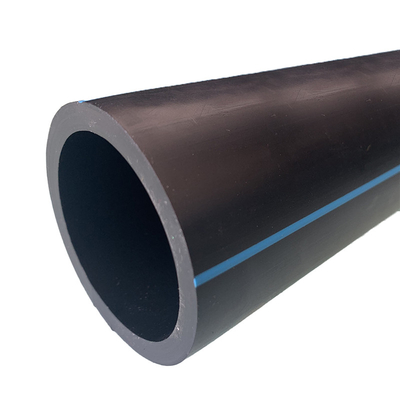

The main features of HDPE pipes are: good toughness and flexibility; small friction coefficient and strong passing ability; convenient construction, good chemical stability, long service life, suitable deflection, good resistance to rapid crack transmission, resistance to Low temperature, conform to the requirements of the times, "green" environmental protection.

| Diameter(mm) |

Outer diameter(mm) |

Wall thickness

(mm) |

Weight/m

(kg) |

Weight/root(kg) |

Root/km |

Weight/km(ton) |

| 80 |

98 |

6 |

12.2 |

76.5 |

167 |

12.77 |

| 100 |

118 |

6.1 |

15.1 |

95 |

167 |

15.87 |

| 150 |

170 |

6.3 |

22.8 |

144 |

167 |

20.05 |

| 200 |

220 |

6.4 |

30.6 |

194 |

167 |

32.4 |

| 250 |

274 |

6.8 |

40.2 |

255 |

167 |

42.59 |

| 300 |

326 |

7.2 |

50.8 |

323 |

167 |

53.94 |

| 350 |

378 |

7.7 |

63.2 |

403 |

167 |

67.3 |

| 400 |

429 |

8.1 |

75.5 |

482 |

167 |

80.48 |

| 450 |

480 |

8.6 |

89.3 |

575 |

167 |

95.86 |

| 500 |

532 |

9 |

104.3 |

669 |

167 |

111.72 |

| 600 |

635 |

9.9 |

137.3 |

882 |

167 |

147.29 |

| 700 |

738 |

10.8 |

173.9 |

1123 |

167 |

187.54 |

| 800 |

842 |

11.7 |

215.2 |

1394 |

167 |

232.8 |

| 900 |

945 |

12.6 |

260.2 |

1691 |

167 |

282.4 |

| 1000 |

1048 |

13.5 |

309.3 |

2017 |

167 |

336.84 |

| 1200 |

1255 |

15.3 |

420.1 |

2758 |

167 |

460.69 |

Advantage

1. Excellent resistance to rapid crack propagation (RCP).

2. Excellent flexibility and scratch resistance.

3. Good wear resistance, low wall friction coefficient, low flow resistance, and excellent conveying capacity.

4. A variety of non-excavation methods can be used, and the construction and installation are extremely convenient.

5. The system cost is low, and the maintenance cost is low, which can greatly reduce the project cost.

Details

Application

Material and liquid transportation pipelines in chemical, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, papermaking, metallurgy and other industries.

Agricultural irrigation pipes.

Posts and telecommunications lines, power wire protection casing.

Mine mortar pipeline.

Certificate

Company Profile

High Mountain Pipe Management Industry With 19 years of experience in R&D, production and sales of plastic pipe fittings, HDPE pipes are of good quality. In order to meet the actual needs of modern high-quality buildings and the design concept of environmental protection and silence, the company has introduced advanced production equipment and manufacturing technology, and has successively developed grooved ( HDPE) HDPE mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and HDPE siphon drainage system series products. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. hdpe pipe factory adheres to the factory policy of "credibility, quality and management as the fundamental goal", with moderate price, dedicated service, and customer satisfaction as the purpose, abiding by contracts and keeping promises and famous all over the country.

FAQ

Q: How is your price?

A: Although we have brand-name products, our prices are very favorable and competitive. Because of our best price, customers from all over the world come to purchase our products.

Q: After reading your FAQ, I am very satisfied. How can I start buying my order?

A: Please contact our sales manager by email or phone, thank you.

Q: What are raw materials?

A: PE.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!