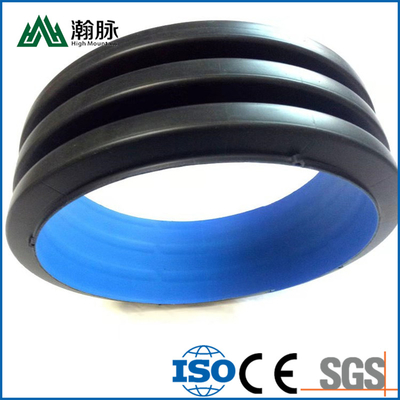

HDPE Double Wall Corrugated Drainage Pipe Customized Size And Color Drainage Plastic Pipes

----------------------------------------

Basic Info.

What should be paid attention to during the construction and installation of double wall corrugated pipe?

(1) The spigot shall be in the direction of water flow and the socket shall be in the direction of reverse water flow;

⑵ The adjusted pipe should be vertical and flat when it is broken;

(3) During the interface operation, the internal and external work of the socket and spigot shall be cleaned first, and the rubber ring shall be checked to see if it is complete;

(4) The central axis of the socket must be aligned with the central axis of the socket.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

1. Good impact resistance at low temperature: The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60 °C. During construction in winter, due to the good impact resistance of the material, the pipe will not be brittle.

2. Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

3. Good chemical corrosion resistance: HDPE pipes are resistant to corrosion by a variety of chemical media, and the chemicals present in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it does not rot, rust or electrochemically corrode; it also does not promote algal, bacterial or fungal growth.

4. Anti-aging and long service life: Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

Details

Application

1,Municipal engineering: used as drainage and sewage pipe.

2,Construction engineering: used as building rainwater pipes, underground drainage pipes, sewage pipes, ventilation pipes.

3,Railway and highway communication equipment: used as the protection pipe of communication cable and optical fiber cable.

4,Industrial: Widely used as sewage pipes in chemical, hospital, environmental protection and other industries.

5,Agricultural garden engineering: used for farmland, fruit and tea garden, and forest belt drainage pipe.

6,Road engineering: used as the seepage and drainage pipe of railroad and highway.

7,Mine: used as mine ventilation, air supply and drainage pipe.

Certificate

Company Profile

High Mountain Pipe is a production enterprise focusing on core technology of pipelines.

The company introduced advanced production equipment and manufacturing technology, and successively developed grooved (HDPE) high-density polyethylene mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and high-density polyethylene siphon drainage system. Series products.

FAQ

Q:Is the price on this page correct?

A: The listed price is only for reference, for latest price, pls contact us directly.

Q: Is it possible to use the label or packaging I specified?

A: Yes. If necessary, we would like to use labels or packaging according to your requirements.

Q: How do you guarantee that the products you provide are qualified?

A: We always believe that integrity and responsibility are the foundation of a company, so any products we provide you are qualified. We will test the goods and provide COA before delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!