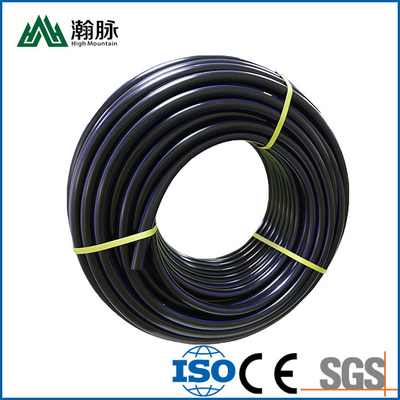

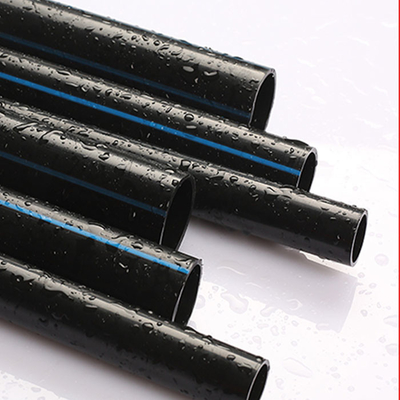

PE Pipe High-Density Water Pipe Anti-Freeze And Anti-Corrosion Polyethylene Pipes HDPE Water Supply Pipe 25

----------------------------------------

Basic Info.

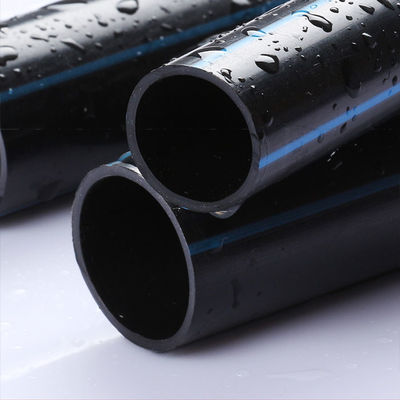

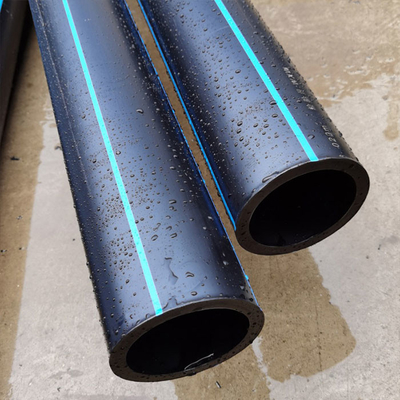

High-density polyethylene (HDPE) pipe is made of high-density polyethylene resin extruded through an extruder. The product is resistant to aging, high in strength, and good in wear resistance. At the same time, it has excellent corrosion resistance, impact resistance, low temperature resistance, self-lubrication, and low flow resistance. It is suitable for the transportation of corrosive media such as water supply, pharmacy, chemical industry, sewage, mortar, and rainwater pipes in high-rise buildings.

Outer Diameter

DN (mm) |

SDR 9

PN20 |

SDR 11

PN16 |

SDR 13.6

PN12.5 |

SDR 17

PN10 |

SDR21

PN8 |

SDR26

PN6 |

Packing

Loaded into 40GP/Piece

6m or 12m per Piece |

| |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

1085 |

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

754 |

| 110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

504 |

| 125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

378 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

304 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

224 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

182 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

143 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

110 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

90 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

72 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

56 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

42 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

30 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

25 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

20 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

16 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

12 |

| 710 |

|

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

9 |

| 800 |

|

72.7 |

58.8 |

47.4 |

38.1 |

30.6 |

6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

6 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

4 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

|

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

|

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

|

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

|

Advantage

1. The polyethylene pipe systems are connected by electric heat melting, and the strength of the joint is higher than the strength of the pipe body.

2. The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60℃. During construction in winter, because the material has good impact resistance, the pipe will not be brittle.

3. HDPE pipe has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

4. HDPE pipes are resistant to corrosion by a variety of chemical media, and the chemical substances in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; in addition, it will not promote the growth of algae, bacteria or fungi.

5. Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

6. The comparison test of the wear resistance of HDPE pipes and steel pipes shows that the wear resistance of HDPE pipes is 4 times that of steel pipes. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipes, which means that HDPE pipes have a longer service life and better economy.

7. The flexibility of HDPE pipeline makes it easy to bend. In engineering, obstacles can be bypassed by changing the direction of the pipeline. In many cases, the flexibility of the pipeline can reduce the amount of pipe fittings and reduce installation costs.

Details

Application

Urban tap water pipe network system;

Urban and rural drinking water pipelines;

Agricultural irrigation pipes;

Mine mortar conveying pipeline;

Protective sleeves for post and telecommunications lines and power wires;

Material and liquid transportation pipelines in chemical, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, papermaking, metallurgical and other industries.

Certificate

Company Profile

High Mountain Pipe Industry is a specialized enterprise that produces anticorrosive plastics (pp, frpp, pe, hdpe, pvdf, pph, upvc, cpvc, abs) pipes, fittings, plates, and valves. The company has various assets of more than 61.8 million yuan, 10 pipe production lines, 2 pipe fittings production lines, and 1 sheet production line. It has a production capacity of more than 8,000 tons of various anti-corrosion plastic products. The pipe production caliber can reach 1200mm, the plate production width can reach 2000mm, and the length is unlimited. In 2006, the company passed ISO9001-2000 quality management system certification, ISO14001 environmental system certification, OHSA18001 occupational health and safety system certification, CMMI certification, and IEC27001 information security system certification.

The company adheres to the people-oriented scientific development concept, correctly grasps product development trends, implements strategic target management, is committed to developing core manufacturing advantages, optimizing resource allocation and technological breakthroughs, introducing market-oriented and refined operating systems, achieving leapfrog development, and striving to build " "Rongchengxing" brand, implement a win-win strategy, and work hard for the development of the industry!

FAQ

Q: What are raw materials?

A: PE

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Q: After reading your FAQ, I am very satisfied. How can I start buying my order?

A: Please contact our sales manager by email or phone, thank you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!