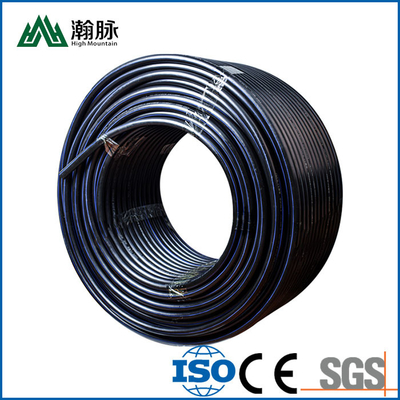

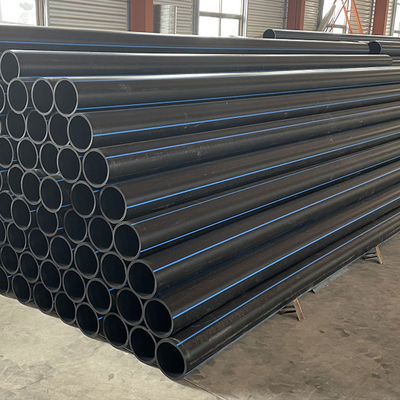

PE Tap Water Pipe 4 Inch HDPE Household Water Supply Pipe 20 25 32 Hot Melt Large Diameter Irrigation Household Hard Pipes

----------------------------------------

Basic Info.

HDPE pipes are the replacement products of traditional steel pipes and PVC drinking water pipes.

The water supply pipe must bear a certain pressure, usually a PE resin with a large molecular weight and good mechanical properties, such as HDPE resin, should be used. LDPE resin has low tensile strength, differential pressure resistance, poor rigidity, poor dimensional stability during molding and difficult connection, and is not suitable as a material for water supply pressure pipes. However, due to its high hygienic index, LDPE, especially LLDPE resin, has become a common material for the production of drinking water pipes. LDPE and LLDPE resins have low melt viscosity, good fluidity and easy processing, so their melt index can be selected in a wide range, usually MI is between 0.3-3g/10min

| SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

| Pressure 0.6Mpa |

Pressure 0.8Mpa |

Pressure 1.0Mpa |

Pressure 1.25Mpa |

Pressure 1.6Mpa |

| Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

Outer diameter mm |

Thick mm |

| 110 |

4.2 |

90 |

4.3 |

75 |

4.5 |

63 |

4.7 |

20 |

2.3 |

| 125 |

4.8 |

110 |

5.3 |

90 |

5.4 |

75 |

5.6 |

25 |

2.3 |

| 140 |

5.4 |

125 |

6 |

110 |

6.6 |

90 |

6.7 |

32 |

3 |

| 160 |

6.2 |

140 |

6.7 |

125 |

7.4 |

110 |

8.1 |

40 |

3.7 |

| 180 |

6.9 |

160 |

7.7 |

140 |

8.3 |

125 |

9.2 |

50 |

4.6 |

| 200 |

7.7 |

180 |

8.6 |

160 |

9.5 |

140 |

10.3 |

63 |

5.8 |

| 225 |

8.6 |

200 |

9.6 |

180 |

10.7 |

160 |

10.8 |

75 |

6.8 |

| 250 |

9.6 |

225 |

10.8 |

200 |

11.9 |

180 |

13.3 |

90 |

8.2 |

| 280 |

10.7 |

250 |

11.9 |

225 |

13.4 |

200 |

14.7 |

110 |

10 |

| 315 |

12.1 |

280 |

13.4 |

250 |

14.8 |

225 |

16.6 |

125 |

11.4 |

| 355 |

13.6 |

315 |

15 |

280 |

16.6 |

250 |

18.4 |

140 |

12.7 |

| 400 |

15.3 |

355 |

16.9 |

315 |

18.7 |

280 |

20.6 |

160 |

14.6 |

| 450 |

17.2 |

400 |

19.1 |

355 |

21.1 |

315 |

23.2 |

180 |

16.4 |

| 500 |

19.1 |

450 |

21.5 |

400 |

23.7 |

355 |

26.1 |

200 |

18.2 |

| 560 |

21.4 |

500 |

23.9 |

450 |

26.7 |

400 |

29.4 |

225 |

20.5 |

| 630 |

24.1 |

560 |

26.7 |

500 |

29.7 |

450 |

33.1 |

250 |

22.7 |

| 710 |

27.2 |

630 |

30 |

560 |

33.2 |

500 |

36.8 |

280 |

25.4 |

| 800 |

30.6 |

710 |

33.9 |

630 |

37.4 |

560 |

41.2 |

315 |

28.6 |

| 900 |

34.4 |

800 |

38.1 |

710 |

42.1 |

630 |

46.3 |

355 |

32.2 |

| 1000 |

38.2 |

900 |

42.9 |

800 |

47.4 |

710 |

52.2 |

400 |

36.3 |

| 1200 |

45.9 |

1000 |

47.7 |

900 |

53.3 |

800 |

58.8 |

450 |

40.9 |

| |

|

1200 |

57.2 |

1000 |

59.3 |

|

|

500 |

45.4 |

| |

|

|

|

|

|

|

|

560 |

50.8 |

| |

|

|

|

|

|

|

|

630 |

57.3 |

Advantage

1. Flexibility: Because PE-RT is relatively soft. Therefore, no special tools are required during construction, so the construction cost is relatively low.

2. Thermal conductivity: pipes used for floor heating need to have good thermal conductivity. PE-RT has better thermal conductivity, and its thermal conductivity is twice that of PP-R and PP-B pipes. It is very suitable for floor heating.

3. High temperature resistance: The high temperature resistance of PE-RT can reach 90°C, while that of PEX can only reach 65°C.

4. Low temperature thermal shock resistance: PE-RT has better low temperature shock resistance. During winter construction, the pipes are not susceptible to being impacted and broken, which increases the flexibility of construction arrangements.

5. Environmental protection: PE-RT and PP-R can be recycled and will not pollute the environment. The PEX cannot be recycled will cause secondary pollution;

6. Stability of processing performance: PEX has the problems of controlling the degree of cross-linking and cross-linking uniformity. The processing is complicated and the processing directly affects the performance of the pipe. However, PE-RT and PP-R are easy to process, and the performance of the pipe is basically determined by the raw material, and the performance is relatively stable. PE-RT is the abbreviation of Polyethylene Raised Temperature. It is a copolymer of ethylene monomer and 1-octene monomer. It is a medium-density ethylene-octene copolymer specially designed for heating systems. It has a narrow molecular weight distribution. , The special molecular structure of octene evenly distributed on the polymer backbone, it not only retains the original advantages of PE's sanitary performance and processing performance, but also strengthens the high temperature durability of a new type of special pipe material. The pipes produced with this raw material are mainly used in the field of hot water/heating pipes in buildings, and their durability is the same as the life of the building, up to 50 years at least, and also has good recyclability and high added value.

Details

Application

1. Urban tap water pipe network system.

2. Urban and rural drinking water pipelines.

3. Material and liquid transportation pipelines in chemical, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, papermaking, metallurgical and other industries.

4. Agricultural irrigation pipes.

5. Protection sleeves for post and telecommunications lines and power wires.

6. Mine mortar conveying pipeline.

7. Protection sleeves for post and telecommunications lines and power wires.

Certificate

Company Profile

High Mountain Pipe is A company specializing in the production of PE water supply pipes, PE gas pipes and PE flame-retardant, anti-static mining pipes, PE ground source heat pump pipes, PE siphon drainage pipes, PERT floor heating pipes and supporting PE water supply pipes, PE gas pipes, PE flame retardant, anti- High-tech enterprise of series products such as double-resistance pipe fittings for electrostatic mine, PE ground source heat pump pipe fittings, PE sprayed anticorrosive steel flanges, PE ball valves, PERT floor heating pipe fittings, PE siphon drainage pipe fittings, etc.

FAQ

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Q: Can I customize the size I need?

A: Yes

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!