90mm 110mm Hdpe Storm Sewer Multipurpose For Groundwater Supply Systems

----------------------------------------

Basic Info.

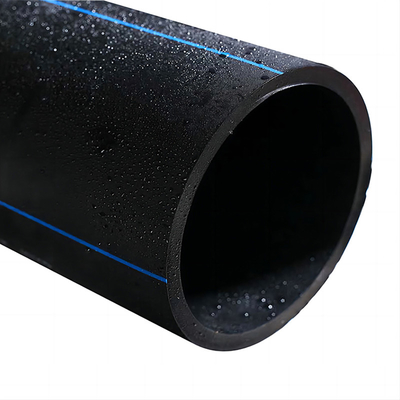

What are the structural components of HDPE pipes?

The excellent performance of HDPE pipes is inseparable from its unique structural components. HDPE is a high-density variant of polyethylene with higher molecular density and stronger intermolecular forces. This gives HDPE excellent mechanical properties, chemical resistance and high temperature resistance. The manufacture of HDPE pipes typically involves the extrusion of polyethylene resin, ensuring the pipes have uniform thickness and good durability. The construction components of HDPE pipe provide a solid foundation for its superior performance in a variety of environmental and engineering conditions.

| Size |

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 20 |

2.3 |

2.3 |

|

|

|

|

| 25 |

3.0 |

2.3 |

2.3 |

|

|

|

| 32 |

3.6 |

3.0 |

2.4 |

|

|

|

| 40 |

4.5 |

3.7 |

3.0 |

2.4 |

|

|

| 50 |

5.6 |

4.6 |

3.7 |

3.0 |

|

|

| 63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 110 |

12.3 |

10.0 |

8.1 |

6.6 |

5.3 |

4.2 |

| 125 |

14.0 |

11.4 |

9.2 |

7.4 |

6.0 |

4.8 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15.0 |

12.1 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30.0 |

24.1 |

| 710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

1. Durability: HDPE drainage pipes are incredibly durable and long-lasting. They can withstand extreme weather conditions, heavy loads, and high traffic areas. HDPE pipes have a lifespan of up to 100 years, making them a cost-effective choice for drainage systems.

2. Chemical Resistance: HDPE is resistant to a wide range of chemicals, making it an ideal choice for drainage systems that handle chemical waste. The material can withstand exposure to acids, alkalis, and other corrosive substances without degrading.

3. Corrosion Resistance: Unlike metal pipes, HDPE pipes are not susceptible to corrosion. They are immune to rust and other forms of corrosion that can cause leaks and other problems in drainage systems.

4. Lightweight: HDPE pipes are lightweight, making them easy to transport and install. They require fewer workers and less heavy equipment, reducing installation costs.

Details

Application

HDPE pipes are widely used in building water supply, building drainage, buried drainage pipes, building heating, gas transmission pipes, welding and telecommunications maintenance casings, industrial pipes, and agricultural pipes because of their unique advantages. Wait. Its key applications are urban water supply, urban gas supply, farmland irrigation and other industries. PE (polyethylene) raw materials are widely used in the water supply pipe manufacturing industry because of their high strength, corrosion resistance, and non-toxic properties; because it is not easy Rust, therefore, is an ideal pipe to replace ordinary iron water supply pipes.

Certificate

Company Profile

High Mountain Pipe is a production enterprise focusing on core technology of pipelines.

The company introduced advanced production equipment and manufacturing technology, and successively developed grooved (HDPE) high-density polyethylene mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and high-density polyethylene siphon drainage system. Series products.

FAQ

Q: What are raw materials?

A: PE

Q: How to get free samples?

A: Send your address, telephone number, zip code and express account number to our mailbox, and tell us which model of samples you need. Our sales team will contact you within 24 hours.

Q: What is your minimum order quantity?

A: Accessories: one box or one bag.

Pipeline: 200~5000 meters/size, depending on different sizes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!