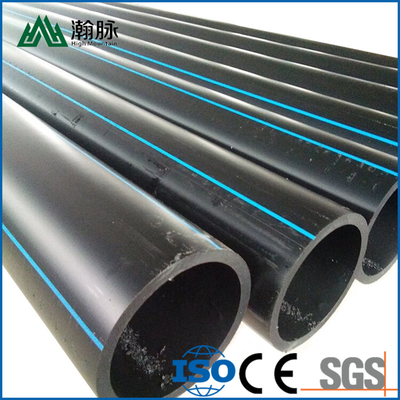

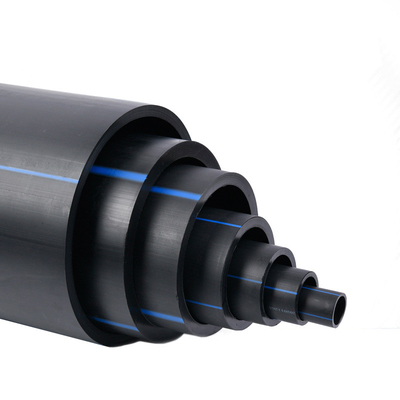

Customization Small Diameter HDPE Water Supply Irrigation Plastic Water Pipe Roll

----------------------------------------

Basic Info.

There are many classification methods of HDPE pipes, which can be divided into water supply pipes, gas pipes, aluminum-plastic composite pipes, buried drainage pipes, agricultural irrigation pipes and electrical casings according to the application field; according to the pressure conditions, they can be divided into pressure pipes and non-pressure pipes. , water supply pipes and gas pipes belong to the category of pressure pipes.

In recent years, with the application of HDPE pipe more and more widely. Density alone cannot accurately reflect the essential performance of PE as a pipe. At present, the unified classification method is to classify the pipe and its raw materials according to the long-term hydrostatic strength of the PE pipe, which is divided into PE 32, PE 40, and PE 63. PE80, PE100. Among them, the PE 80 and PE 100 grade pipes can be used to transport gas, while the pipes below the PE 63 grade are mainly used for hot water pipes and sewage and irrigation pipes.

Outer Diameter

DN (mm) |

SDR 9

PN20 |

SDR 11

PN16 |

SDR 13.6

PN12.5 |

SDR 17

PN10 |

SDR21

PN8 |

SDR26

PN6 |

Packing

Loaded into 40GP/Piece

6m or 12m per Piece |

| |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

1085 |

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

754 |

| 110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

504 |

| 125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

378 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

304 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

224 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

182 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

143 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

110 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

90 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

72 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

56 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

42 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

30 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

25 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

20 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

16 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

12 |

| 710 |

|

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

9 |

| 800 |

|

72.7 |

58.8 |

47.4 |

38.1 |

30.6 |

6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

6 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

4 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

|

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

|

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

|

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

|

Advantage

1. A variety of non-excavation methods can be used, and the construction and installation are extremely convenient.

2. The system cost is low, and the maintenance cost is low, which can greatly reduce the project cost.

3. No leakage: PE pipe adopts electrofusion connection, and its interface strength is higher than the pipe itself.

4. High toughness: The elongation at break of PE pipe is generally above 500%.For the uneven settlement of the base layer, its adaptability is very strong and the seismic performance is good.

5. Excellent resistance to rapid crack propagation (RCP).

6. Excellent flexibility and scratch resistance.

7. Good wear resistance, low wall friction coefficient, low flow resistance, and excellent conveying capacity.

Details

Application

1. Polyurethane coating

It is a new type of green special coating developed to meet the needs of environmental protection, with good wear resistance and corrosion resistance.

2. Epoxy coal pitch coating

Epoxy coal tar coating is not only suitable for gas pipelines, but also for sewage pipelines. It is a two-component coating that has high adhesion and a very smooth surface

3. Epoxy ceramic lining

Epoxy ceramic lining is suitable for sewage pipelines and gas pipelines, but due to the difficult manufacturing process and high cost, it has certain limitations in use. Epoxy ceramic lining has high adhesion and smoothness, and is a good anti-corrosion coating.

4. Aluminate cement coating or sulfate cement coating

Both of these special cement coatings are suitable for the internal anti-corrosion of ductile iron pipes used in sewage pipelines to improve the corrosion resistance of the acid and alkali components in the sewage.

Certificate

Company Profile

Our company's products are of high quality, and we always adhere to and implement the quality policy of "Quality is the foundation of a company's survival, and providing users with satisfactory products and services is our eternal pursuit". . Our company is a factory direct sale of ductile iron pipes, ductile iron pipe fittings, ductile iron manhole covers, Xinxing ductile pipes, ductile iron well grate; W type flexible cast iron pipe, W type cast iron drainage pipe and pipe fittings; A type flexible cast iron pipe, A type cast iron drainage Pipes and fittings, B-type flexible cast iron pipes, B-type cast iron drainage pipes and pipe fittings and other products. Our company is a group company integrating production and sales. The annual production capacity of ductile iron pipes and flexible drainage pipes is 300,000 tons; the annual sales volume of ductile iron pipes is 120,000 tons and the annual sales volume of flexible drainage pipes is 180,000 tons.

FAQ

Q: What is the delivery time?

A: We always have common products in stock and can be shipped within 30 days.

Large orders require 15 days to complete production.

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Q: Can you make special designs and logos on your products?

A: Yes, it is very easy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!