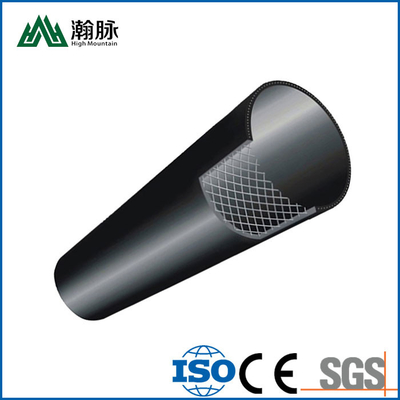

Steel Mesh Skeleton Plastic Polyethylene Composite Pipe PE Water Supply Pipe Fire-Fighting Buried Municipal Drainage

----------------------------------------

Basic Info.

The steel mesh skeleton polyethylene composite pipe is a reticulated skeleton formed by spirally winding high-strength steel wire left and right as the reinforcement, high-density polyethylene (HDPE) as the matrix, and high-performance HDPE modified bonding resin to connect the steel wire skeleton with the inner , A new type of pipe with the outer layer of high-density polyethylene tightly connected together.

| Product name |

HDPE water supply pipe/PE pipe/polyethylene pipe |

| Nominal pressure |

0.6mpa-1.6mpa (SDR26-SDR11) |

| Product color |

Black with 4 eye-catching blue lines |

| Product wall |

Related to model and pressure |

| Product length |

6-12 meters |

| Nominal outer diameter |

dn90-630mm |

Advantage

The steel mesh skeleton polyethylene composite pipe has the common characteristics of plastic pipes such as anti-corrosion, non-scaling, smooth and low resistance, heat preservation without waxing, abrasion resistance, and light weight, and its unique structure also creates the following characteristics:

(1) Good creep resistance, high durable mechanical strength

Because plastics will creep under normal temperature and stress, and brittle fracture will occur under higher permanent stress. Therefore, the allowable stress and pressure-bearing capacity of pure plastic pipes are very low (generally within 1.0Mpa). The mechanical strength of steel is about 10 times that of thermoplastics, and it is very stable and does not creep in the temperature range of plastics. After the mesh steel wire skeleton is compounded with the plastic, the steel wire mesh skeleton can effectively restrain the creep of the plastic, and greatly improve the lasting strength of the plastic itself. Therefore, the allowable stress of the steel mesh skeleton polyethylene composite pipe is doubled than that of the plastic pipe.

(2) Good temperature resistance

The strength of plastic pipes generally decreases with increasing temperature within the temperature range of their use, and the strength decreases by more than 10% for every 10°C increase in temperature. Because about 2/3 of the strength of the steel wire mesh skeleton polyethylene composite pipe is borne by the steel wire mesh skeleton, its strength decreases with the increase of use temperature lower than that of any pure plastic pipe. The experimental results show that the strength of the steel mesh skeleton polyethylene composite pipe decreases below 5% for every increase of 10°C.

(3) Rigidity, good impact resistance, good dimensional stability, and moderate flexibility, combining rigidity and flexibility

The elastic modulus of steel is usually about 200 times that of high-density polyethylene. Due to the reinforcement of the steel mesh skeleton, the rigidity, impact resistance and dimensional stability of the steel mesh skeleton polyethylene composite pipe are better than any pure pure Plastic pipes. At the same time, because the mesh steel framework itself is a flexible structure, the composite pipe is also flexible in the axial direction. Therefore, the pipe has the characteristics of rigidity and flexibility, and has excellent performance in the adaptability of loading and unloading, transportation, installation and operational reliability. Above-ground installation can save the number of supports and low cost; underground installation can effectively withstand sudden impact loads caused by settlement, slippage, vehicles, etc. Small-caliber pipes can be bent appropriately, arranged undulating or serpentine according to the terrain, saving pipe fittings.

(4) The coefficient of thermal expansion is small

Since the linear expansion coefficient of steel wire for plastic pipe is 10.6~12.2×10-6 (1/℃), the linear expansion coefficient of pure plastic pipe is 170×10-6 (1/℃). Under the constraints of the framework, the thermal expansion of the composite pipe is greatly improved, which is lower than that of any commonly used plastic pipe. Through the test, the expansion coefficient of the steel mesh skeleton polyethylene composite pipeline is 35.4~35.9×10-6 (1/℃), only It is 3 to 3.4 times that of ordinary carbon steel pipes. The experimental results show that the thermal compensation device is generally not needed for buried installation, and the pipes can be laid in a serpentine shape to absorb (or release), thereby reducing the installation cost.

(5) Rapid cracking will not occur

Pure plastic pipes, especially large-caliber pure plastic pipes, are prone to rapid cracking caused by local defects and stress concentration (instantly hundreds of meters to more than kilometers) under the action of long-lasting circumferential stress at low temperatures. Therefore, the current international The rapid cracking resistance of plastics puts forward high requirements, and low carbon steel does not have the problem of brittle fracture. The existence of the steel mesh prevents the deformation and stress of the plastic from reaching the critical point of causing rapid cracking. Therefore, theoretically speaking, there is no rapid cracking in the steel mesh skeleton polyethylene composite pipe.

6) The two materials of steel and plastic are evenly and reliably compounded

The steel-plastic composite pipe currently on the market is a continuous and regular interface between the steel and plastic. It is easy to delamination under the action of alternating stress for long-term use, resulting in leakage at the connection, bottleneck shrinkage inside, and blockage failure. . In contrast, the steel mesh skeleton polyethylene composite pipe is a mesh structure through a special hot melt adhesive (modified HDPE) so that the plastic and the steel mesh are tightly combined and integrated. The binding force of the two materials is large and uniform, and the stress concentration is small.

7) Double-sided anti-corrosion

The steel mesh skeleton is compounded in the plastic through a special hot melt adhesive layer. The inner and outer surfaces of the pipe have the same anti-corrosion performance, wear resistance, smooth inner wall, small conveying resistance, no scaling, no waxing, and obvious energy saving effect. It is used for buried conveying and It is more economical and convenient under corrosive environmental conditions.

(8) Good self-traceability

Due to the presence of the steel mesh skeleton, the buried steel mesh skeleton polyethylene composite pipe can be located by the usual magnetic detection method to avoid damage caused by other excavation projects. And this kind of damage is the most damage caused by pure plastic pipes and other non-metallic pipes.

(9) Convenient and flexible adjustment of product structure and performance

The structure and performance of the product can be adjusted by changing the steel wire diameter, mesh spacing, plastic layer thickness, plastic and type to meet different pressure, temperature, and anti-corrosion requirements.

(10) Dedicated electrofusion joints, diverse in varieties, very fast and reliable in installation

The connection of the steel mesh skeleton polyethylene composite pipe adopts two methods: electric heat fusion connection and flange connection. The electric heat fusion connection is to insert the composite pipe into the electric heat fusion pipe fitting, and energize the electric heating wire pre-buried on the inner surface of the pipe fitting to generate heat. The inner surface of the pipe fitting is melted to produce a melt. The melt expands and fills the gap between the pipe fittings until the outer surface of the pipe also produces a melt. The two melts are melted together. After cooling and forming, the pipe and the pipe fitting are tightly connected as a whole.

Details

Application

1. Municipal engineering: urban water supply, heat network backwater, gas and natural gas transmission pipelines.

2. Chemical engineering: process pipes and discharge pipes for transporting corrosive gases, liquids, and solid powders in acid, alkali, salt manufacturing, petrochemical, fertilizer, pharmaceutical, chemical, rubber and plastic industries.

3. Oil and gas fields: oily sewage, gas field sewage, oil and gas mixtures, pipelines for the gathering and transportation of secondary and tertiary oil recovery.

4. Thermal power engineering: pipelines for process water, return water transportation, dust removal, waste residue, etc.

5. Metallurgical mines: Corrosive medium transportation and ore slurry and tailings process pipes in non-ferrous metal smelting.

6. Expressway: buried drainage pipes, cable transmission conduits

7. Marine engineering: sea water transportation, submarine pipelines and optical (electric) cable conduits, etc.

8. Shipbuilding: ship sewage pipes, drain pipes, ballast pipes, ventilation pipes

Certificate

Company Profile

High Mountain Pipe Management Industry is located in Jiangyin City, with convenient water and land transportation. It is a comprehensive company integrating R&D, design, application, production and sales. The company has equipment to produce large-diameter HDPE water supply pipe production line, prestressed corrugated pipe, corrugated pipe production line, and PVC pipe production line. We specialize in the production of PE water pipes, prestressed corrugated pipes, HDPE corrugated pipes, plastic blind trenches, permeable pipes, etc. These products are mainly used in municipal administration, roads, railways, water conservancy, electricity, environmental greening and infrastructure construction. , And used for municipalities and highways. Major projects in many countries, such as railways and railways, are highly praised by engineering professionals and users.

FAQ

Q: What are raw materials?

A: PE

Q: Why choose us?

A: We are a professional manufacturer with competitive price, excellent quality and fast delivery time.

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!