High Density Polyethylene Pipe 110mm 4 Inch Upvc Drainage Plastic Price Hdpe Pipe Plastic Drain Pipes For Water

----------------------------------------

Basic Info.

Drainage Safety:

The orifice is located in the trough of the wave. Due to the two-way action of the wave crest and the filter fabric, the orifice is not easy to be blocked, which ensures the smooth flow of the permeable system.

Corrosion resistance:

Plastic is less prone to rusting than soft spring drains.

The organic combination of strength and flexibility:

The unique double corrugated structure effectively improves the external pressure strength of the product, and the drainage system will not be deformed by external pressure and affect the drainage effect.

Economical:

Compared with other drain pipes of the same diameter, its price is lower.

| Model (inner diameter) |

| Ф20 |

Ф25 |

Ф32 |

Ф40 |

Ф50 |

Ф63 |

Ф75 |

Ф90 |

| Ф110 |

Ф125 |

Ф140 |

Ф160 |

Ф180 |

Ф200 |

Ф225 |

Ф250 |

| Ф280 |

Ф315 |

Ф355 |

Ф400 |

Ф450 |

Ф500 |

Ф560 |

Ф630 |

| Ф710 |

Ф800 |

Ф900 |

Ф1000 |

Ф1200 |

|

|

|

Advantage

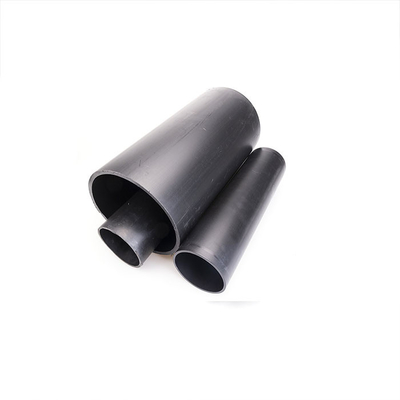

1. Strong pressure resistance

The internal structure of the HDPE drainage pipe is relatively smooth, which greatly enhances the ring stiffness of the pipe, thereby enhancing the resistance of the pipe to soil loads.

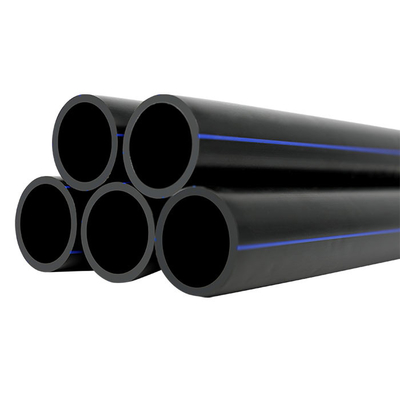

2. Small friction coefficient and strong passing ability

The friction coefficient of the inner wall of the HDPE drainage pipe is 0.009, while that of the reinforced concrete pipe is 0.013. Therefore, the HDPE drainage pipe can pass a larger flow than other pipes of the same diameter.

3. Convenient construction

Due to the light weight of the HDPE pipe, it is easy to handle and connect, so the construction speed is fast. In the case of tight construction period and poor construction conditions, its advantages are more obvious.

4. Good chemical stability and long service life

HDPE molecules have no polarity, so they have good chemical stability. Generally, factors such as soil, electricity, acid and alkali in the environment will not damage the pipeline. In the case of burial, the service life of HDPE pipe can reach more than 50 years.

5. Appropriate deflection

HDPE drainage pipe is a flexible pipe, which can resist a certain degree of uneven settlement of the foundation, and the pipe interface is tight and no leakage.

6. Green and environmental protection

Conform to the requirements of the times, green and environmental protection. The pipe meets the national environmental protection requirements, is non-polluting, non-toxic, and can be recycled.

Details

Application

1. Descending

The problem of drainage on the same floor The descending plate type drainage on the same floor needs to consider the installation space of the pipeline, the height of the structural plate is 300mm, the structural treatment is more difficult, the load-bearing requirements of the decorative layer are higher, and the design load requirements of the descending plate part are larger. If the pipeline leaks in the floor interlayer, the toilet floor must be destroyed, and the maintenance of the pipeline is more difficult.

2. Wall row

(False wall) The problem structure of drainage on the same floor does not need to be lowered, and the drainage pipes are directly laid on the floor using the hidden space of the false wall. The lining wall of the wall-row type drainage on the same floor occupies the space for use in the bathroom, and the selection range of sanitary ware is small. The selection of sanitary ware must conform to the installation height of the wall drainage.

3. Cushion type

The problem of same-layer drainage The cushion-type same-layer drainage achieves the purpose of same-layer drainage by raising the toilet floor and arranging horizontal drainage pipes in the cushion. The main disadvantage is that light fillers need to be filled in the cushion, and the pipeline is easily damaged by extrusion in the cushion. The reminder of the drainage pipe is the same as that of the descending plate type drainage on the same floor. If the pipeline leaks in the floor interlayer, the toilet floor must be destroyed, and the maintenance of the pipeline is more difficult.

4. Countermeasures

At present, there are some better solutions for the difficulties encountered in the same-layer drainage technology, such as the treatment of the descending plate structure, the popularization of special sanitary ware and drainage accessories for the same-layer drainage, etc. In view of the problem that the traditional drainage UPVC pipe is easy to leak, it is possible to set up trenches and repair cover plates in the sinking space of the same layer of drainage...or place the drainage horizontal pipe in the special inspection well and the drainage horizontal pipe in the special equipment layer. Drainage practices.

But these practices only make repairs possible, and are still cumbersome to deal with. In the promotion and application of the same-layer drainage, the most unacceptable problem is the leakage of the pipeline. No matter in the sinker, the cushion, or the false wall, once the pipeline leaks, the maintenance and treatment are troublesome, and it is easy to cause toilet pollution, etc. Bacterial growth, etc.

Certificate

Company Profile

High Mountain Pipe Management Industry With 19 years of experience in R&D, production and sales of plastic pipe fittings, HDPE pipes are of good quality. In order to meet the actual needs of modern high-quality buildings and the design concept of environmental protection and silence, the company has introduced advanced production equipment and manufacturing technology, and has successively developed grooved ( HDPE) HDPE mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and HDPE siphon drainage system series products. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. hdpe pipe factory adheres to the factory policy of "credibility, quality and management as the fundamental goal", with moderate price, dedicated service, and customer satisfaction as the purpose, abiding by contracts and keeping promises and famous all over the country.

FAQ

Q: What is the delivery time?

A: We always have common products in stock and can be shipped within 30 days.

Large orders require 15 days to complete production.

Q: How to get free samples?

A: Send your address, telephone number, zip code and express account number to our mailbox, and tell us which model of samples you need. Our sales team will contact you within 24 hours.

Q: What are your payment terms?

A: Accept the T/T and L/C terms.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!