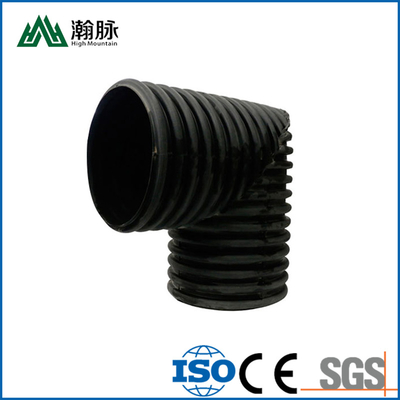

Double Wall Bellows Drain-Pipe Welded Elbow Inspection Well Joints HDPE Pipe Fittings

----------------------------------------

Basic Info.

HDPE drainage pipe is a thermoplastic pipe material, the matrix is mainly high-density polyethylene resin, and it is used for plastic pipes without internal pressure after extrusion molding. The raw material is white powder or granular, non-toxic, tasteless, and has the advantages of corrosion resistance, aging resistance, impact resistance and crack resistance.

Outer Diameter

DN (mm) |

SDR 9

PN20 |

SDR 11

PN16 |

SDR 13.6

PN12.5 |

SDR 17

PN10 |

SDR21

PN8 |

SDR26

PN6 |

| |

Wall Thick Ness(mm) |

| 20 |

2.3 |

2.3 |

|

|

|

|

| 25 |

3 |

2.3 |

2.3 |

|

|

|

| 32 |

3.6 |

3 |

2.4 |

|

|

|

| 40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 710 |

|

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 800 |

|

72.7 |

58.8 |

47.4 |

38.1 |

30.6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2

|

Advantage

1. Reliable connection: The polyethylene piping systems are connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body.

2. Good impact resistance at low temperature: The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60 °C. During construction in winter, due to the good impact resistance of the material, the pipe will not be brittle.

3. Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

4. Good chemical corrosion resistance: HDPE pipes are resistant to corrosion by a variety of chemical media, and the chemicals present in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it does not rot, rust or electrochemically corrode; it also does not promote algal, bacterial or fungal growth.

5. Anti-aging and long service life: Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

6. Good wear resistance: the comparison test of wear resistance between HDPE pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipes, which means that HDPE pipes have longer service life and better economy.

7. Good flexibility: the flexibility of HDPE pipe makes it easy to bend. In engineering, obstacles can be bypassed by changing the direction of the pipe. In many cases, the flexibility of the pipe can reduce the amount of pipe fittings and reduce the installation cost.

8. Low flow resistance: HDPE pipe has a smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non adhesion characteristics ensure that HDPE pipes have higher transportation capacity than traditional pipes, and also reduce the pressure loss and water transmission energy consumption of the pipeline.

9. Convenient handling: HDPE pipes are lighter than concrete pipes, galvanized pipes and steel pipes. It is easy to handle and install, and the lower labor and equipment requirements mean that the installation cost of the project is greatly reduced.

10. A variety of new construction methods: HDPE pipeline has a variety of construction technologies. In addition to the traditional excavation method, it can also use a variety of new non excavation technologies, such as pipe jacking, directional drilling, lining, pipe cracking and so on. This is the only choice for some places where excavation is not allowed. Therefore, HDPE pipeline is widely used.

Details

Application

1) Urban water supply: PE pipe head has comprehensive advantages such as safety, sanitation, and convenient construction, and has become an ideal pipe for urban water supply.

2) Natural gas and gas transmission: PVC has become the best choice for medium and low pressure natural gas transmission pipelines due to a series of advantages such as reliable PE pipeline connection, stable performance, easy construction and corrosion resistance.

3) Food chemical industry: PE pipes have unique corrosion resistance and can be used for the transportation or discharge of various salty and sour salts, resulting in long service life, low cost and low maintenance cost.

4) Ore sand and mud transportation: PE pipe has a unique wear resistance that is 4 times that of steel pipe. It can be widely used to transport ore, fly ash of power plants, mud for river dredging, etc.

5) Replacement of cement pipes, cast iron pipes and steel pipes: For the replacement of old pipes with cement pipes, cast iron pipes, etc. originally laid in the city, PE pipes can be directly inserted into the old pipes for replacement without extensive excavation, and the project cost is low , The construction time is short, especially suitable for the pipeline re-selection in the old city.

6) Landscaping pipe network: landscaping requires a large number of water pipelines, and PE pipes have low cost and are worthy of vigorous promotion.

Certificate

Company Profile

High Mountain Pipe has passed ISO 9001, ISO 14001, OHSAS 18001 management system certification and China environmental labeling product certification. The company is applying for CQC (China Quality) certification and CNAS (China National Accreditation Service for Conformity Assessment) national laboratory qualification accreditation. The company adheres to the business philosophy of "integrity, modesty, and a long history".

Long-term stock products: FRPP pipes, HDPE pipes, PP pipes, PPH pipes, PP boards, PE boards, UHMWPE boards and all pipe fittings.Pipes and plates with special quality requirements and colors, large quantities can be customized according to customer requirements and colors.

FAQ

Q: Which payment is available for your company?

A: T/T, L/C or Ali trade insurance. You can choose the one which is convenient for you.

Q: What is the delivery time?

A: We always have common products in stock and can be shipped within 30 days.

Large orders require 15 days to complete production.

Q: What are raw materials?

A: PE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!