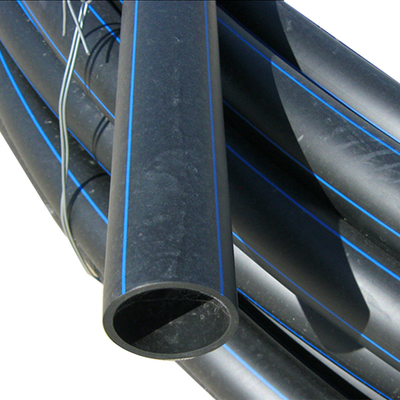

20mm-1200mm Polyethylen Hdpe Pipe Sdr11 Hdpe Poly Water Pipes 2inch Hdpe Pipe

----------------------------------------

Basic Info.

HDPE drainage pipe is a replacement product of traditional steel pipes and polyvinyl chloride drainage pipes. It is mainly responsible for drainage of rainwater, sewage, irrigation and drainage of farmland, etc. It is widely used in roads, railway subgrades, subway projects, waste landfills, tunnels, etc. , Green belts, sports grounds and slope protection caused by high water content and other drainage fields, as well as underground irrigation and drainage systems for agriculture and horticulture.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

1. Stability of processing performance: PEX has the problems of controlling the degree of cross-linking and cross-linking uniformity. The processing is complicated and the processing directly affects the performance of the pipe. However, PE-RT and PP-R are easy to process, and the performance of the pipe is basically determined by the raw material, and the performance is relatively stable.

2. High temperature resistance: The high temperature resistance of PE-RT can reach 90°C, while that of PEX can only reach 65°C.

3. Low temperature thermal shock resistance: PE-RT has better low temperature shock resistance. During winter construction, the pipes are not susceptible to impact and rupture, which increases the flexibility of construction arrangements.

4. Environmental protection: PE-RT and PP-R can be recycled and will not pollute the environment. The PEX cannot be recycled will cause secondary pollution.

Details

Application

The materials used in HDPE pipes are mainly polyvinyl chloride (PVC), polyethylene (PE) and polypropylene (PP). Compared with other plastic pipes (such as PVC), high-density polyethylene (HDPE) pipes have the characteristics of low density, good toughness, corrosion resistance, good insulation performance, easy construction and installation, and are widely used in municipal and building water supply and drainage, gas , heating and heating, wire and cable threading, agricultural water-saving irrigation and other fields.

Certificate

Company Profile

High Mountain Pipe Management Industry With 19 years of experience in R&D, production and sales of plastic pipe fittings, HDPE pipes are of good quality. In order to meet the actual needs of modern high-quality buildings and the design concept of environmental protection and silence, the company has introduced advanced production equipment and manufacturing technology, and has successively developed grooved ( HDPE) HDPE mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and HDPE siphon drainage system series products. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. hdpe pipe factory adheres to the factory policy of "credibility, quality and management as the fundamental goal", with moderate price, dedicated service, and customer satisfaction as the purpose, abiding by contracts and keeping promises and famous all over the country.

FAQ

Q: What are your payment terms?

A: Accept the T/T and L/C terms.

Q: Which payment is available for your company?

A: T/T, L/C or Ali trade insurance. You can choose the one which is convenient for you.

Q: What are raw materials?

A: PE.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!