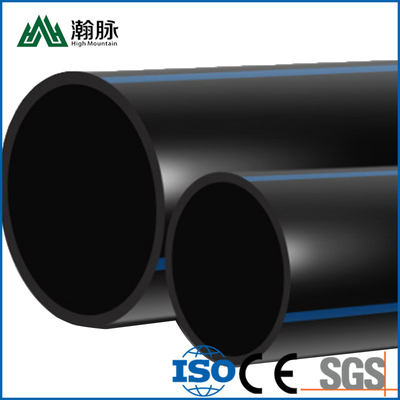

HDPE Water Supply Pipes Pe100 Sdr11 Polyethylene Pipe Price List

----------------------------------------

Basic Info.

HDPE pipe is a highly crystalline, non-polar thermoplastic resin. Generally, the application range of PE pipes for water supply pipelines is below 40°C, and cannot be used for hot water delivery pipelines. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE pipe material has excellent resistance to most household and industrial chemicals. Certain types of chemicals are chemically aggressive, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylene), and halogenated hydrocarbons (carbon tetrachloride).

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

1. Light weight and easy to install and handle;

2. With strong wear resistance and excellent hydraulic performance, no external protection is needed for buried pipelines. It can be applied to earthquake and soil settlement areas in mining areas, and can also be laid at the bottom of rivers by the sinking method.

3. Chemical resistance, internal, external and microbial corrosion resistance, strong corrosion resistance, and healthy. It is suitable for conveying acidic and alkaline substances, sewage, natural gas, coal gas and other substances;

4. Good environmental adaptability and frost resistance. Can be used for indoor and outdoor water supply pipelines.

5. Long service life, with a service life of more than almost 50 years;

6. Easy to recycle.

Details

Application

1. The PE drainage pipe can be connected by hot melt, such as by socket or butt joint. If the diameter of the pipe is relatively small, below DN63 mm, it is more suitable to adopt the method of socket connection.

2. In the specific operation, it is necessary to choose a hot-melt butt welding machine. First, heat the machine to a certain temperature, such as the heating temperature of the PE pipe reaches 230 degrees. After melting, press the two parts that need to be connected, and after cooling and fixing, the purpose of connection can be achieved.

3. You can also choose the way of electrofusion connection. To use an electrofusion welder, insert the pipe into the inside of the machine, melt the surface, and after cooling, the pipe and pipe fittings can be electrofused together. The connection method is very stable and the sealing performance is good.

4. The PE drainage pipe can also be directly connected by flange, select the flange ring of the same specification, and then firmly connect the PE pipe through the flange plate, and the pipe and pipe fittings can achieve the effect of connection.

Certificate

Company Profile

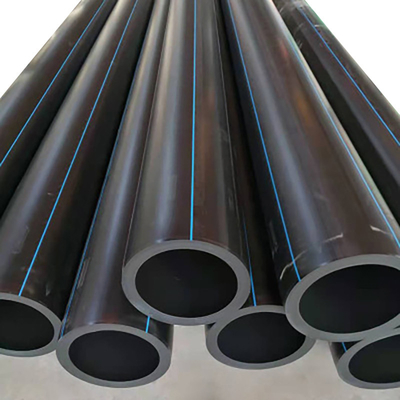

High Mountain Pipe is committed to producing and selling plastic pipes, fittings, valves and related plumbing accessories. by providing professional solutions for water supply systems The production and distribution of our main products, PE Plumbing Pipes and HDPE Drainage Pipes are industry leaders.

Adhering to the corporate philosophy of "people-oriented, honesty and win-win", we are committed to the research and development of new building materials. We are willing to sincerely cooperate with friends from all walks of life to create a better tomorrow.

FAQ

Q: Which payment is available for your company?

A: T/T, L/C or Ali trade insurance. You can choose the one which is convenient for you.

Q: What are raw materials?

A: PE.

Q: Why choose us?

A: We are a professional manufacturer with competitive price, excellent quality and fast delivery time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!