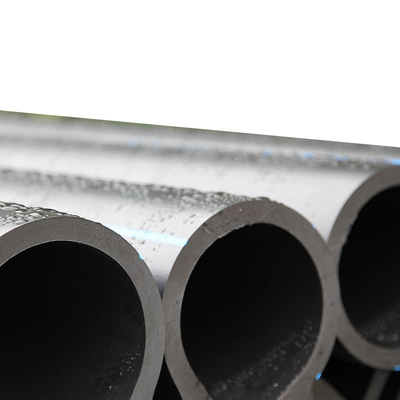

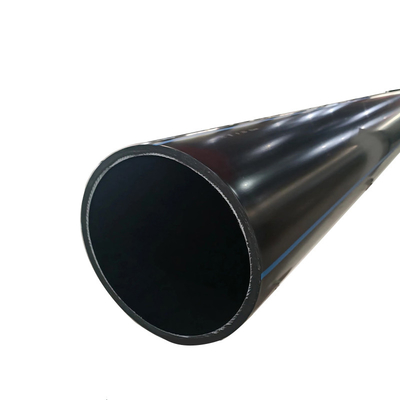

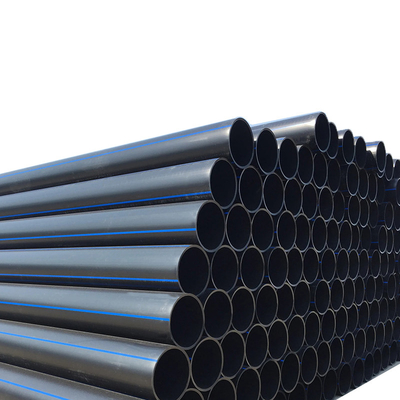

Agricultural Irrigation HDPE Water Supply Pipe Standard Diameter Manufacture

----------------------------------------

Basic Info.

Why use HDPE drainage pipe? 1. Reliable connection: the polyethylene pipe system is connected by electric heating, and the strength of the joint is higher than the strength of the pipe body. 2. Good low-temperature impact resistance: The low-temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60℃. During construction in winter, because the material has good impact resistance, the pipe will not be brittle. 3. Good stress crack resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress crack resistance is also very outstanding.

| Size |

|

PN2.0MPa |

PN1.6MPa |

PN1.25MPa |

PN1.0MPa |

PN0.8MPa |

PN0.6MPa |

| |

|

SDR 9 |

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

| OD(inch) |

OD(mm) |

thickness |

thickness |

thickness |

thickness |

thickness |

thickness |

| 1/2 |

20 |

2.3 |

2.3 |

|

|

|

|

| 3/4 |

25 |

3 |

2.3 |

2.3 |

|

|

|

| 1 |

32 |

3.6 |

3 |

2.4 |

|

|

|

| 1 1/4 |

40 |

4.5 |

3.7 |

3 |

2.4 |

|

|

| 1 1/2 |

50 |

5.6 |

4.6 |

3.7 |

3 |

|

|

| 2 |

63 |

7.1 |

5.8 |

4.7 |

3.8 |

|

|

| 2.5 |

75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

| 3 |

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

| 4 |

110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

| 5 |

125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

| 5 |

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

| 6 |

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

| 7 |

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

| 8 |

200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

| 8 |

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

| 10 |

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

| 11 |

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

| 12 |

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

| 14 |

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

| 16 |

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

| 18 |

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

| 20 |

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

| 22 |

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

| 24 |

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

| 28 |

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

| 32 |

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

| 36 |

900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

| 40 |

1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

| 48 |

1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

| 55 |

1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

| 60 |

1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

| 65 |

1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

Advantage

1. Environmentally friendly materials

The raw material of HDPE pipe mainly comes from polyethylene in Sinopec, which is non-toxic, odorless and non-corrosive. It does not decompose harmful substances in the production process. It is recyclable and easy to process, which is in line with the national policy of developing circular economy.

2. High dielectric strength

HDPE pipe has strong dielectric properties, especially high insulation dielectric strength, especially suitable for wires and cables.

3. Crack resistance

HDPE pipe is stable in structure, not easy to be damaged and cracked, and has a low price. It can effectively reduce noise. It has been gradually applied in building wiring, household appliances, communication equipment, etc.

4. Impact resistance

1) The special structure of HDPE pipe makes it have high mechanical strength and high ring stiffness, and can withstand strong impacts more strongly than traditional pipes, such as areas with multiple earthquakes.

2), the low temperature resistance of HDPE pipe, strong ductility, not easy to be brittle, can resist the impact of extremely cold weather, such as northern China.

5. Wear resistance

The high polymer composition of HDPE pipe is the main reason for its high wear resistance. The wear resistance is even higher than that of most metals, and the self-lubrication is good. It is an ideal pipe.

Details

Application

It is widely used in building water supply, building drainage, buried drainage pipes, building heating, gas transmission and distribution, gas transmission pipes, electrical and telecommunications protection sleeves, industrial pipes, agricultural pipes, etc. It is mainly used in urban water supply, urban gas supply and farmland irrigation.

Certificate

Company Profile

High Mountain Pipe is A company specializing in the production of PE water supply pipes, PE gas pipes and PE flame-retardant, anti-static mining pipes, PE ground source heat pump pipes, PE siphon drainage pipes, PERT floor heating pipes and supporting PE water supply pipes, PE gas pipes, PE flame retardant, anti- High-tech enterprise of series products such as double-resistance pipe fittings for electrostatic mine, PE ground source heat pump pipe fittings, PE sprayed anticorrosive steel flanges, PE ball valves, PERT floor heating pipe fittings, PE siphon drainage pipe fittings, etc.

FAQ

Q: Which payment method can your company use?

A: T/T, L/C or full trade insurance. You can choose the one that is convenient for you.

Q: How and when can I receive my goods after payment?

A: For small batch products, they will be delivered to you by international express (DHL, FedEx, TNT, etc.) or by air. It usually takes 3-5 days to receive the goods after delivery. For high-volume products, it is worthwhile to see the goods and deliver them. It takes several days to several weeks to reach the destination port, depending on the location of the port.

Q: How to buy products?

A: Send an email to us and we will get back to you within one day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!