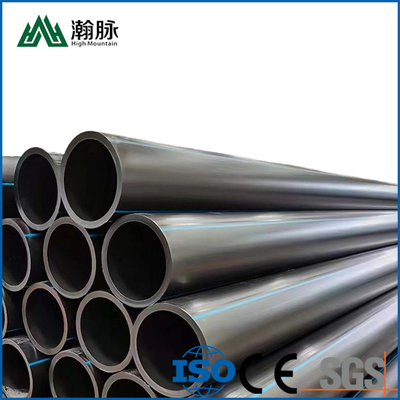

High Quality HDPE Water Supply And Drainage Plastic Pipe Prices Sewage Pipe

----------------------------------------

Basic Info.

PE water supply and drainage hot melt butt joint steps

1. Put in the PE pipe to be welded, fasten the fixture, and adjust the amount of misalignment

2. Put in the port milling cutter to correct the port plane until continuous chips are formed, take out the milling cutter and adjust it again to check the coaxiality

3. Put the preheated heating plate into the middle of the rack, and close the port for port heating

4. take out the heating plate after absorbing heat within the specified time

5. Quickly close the fixture, close the PE water supply pipe to be welded, and steadily increase the pressure

6. Keep the pressure until the interface part cools and reduce the pressure to zero, then loosen the clamp to take out the pipe and complete the welding.

Outer Diameter

DN (mm) |

SDR 9

PN20 |

SDR 11

PN16 |

SDR 13.6

PN12.5 |

SDR 17

PN10 |

SDR21

PN8 |

SDR26

PN6 |

Packing

Loaded into 40GP/Piece

6m or 12m per Piece |

| |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

1085 |

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

754 |

| 110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

504 |

| 125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

378 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

304 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

224 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

182 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

143 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

110 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

90 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

72 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

56 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

42 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

30 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

25 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

20 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

16 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

12 |

| 710 |

|

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

9 |

| 800 |

|

72.7 |

58.8 |

47.4 |

38.1 |

30.6 |

6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

6 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

4 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

|

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

|

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

|

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

|

Advantage

1. Crack resistance

HDPE pipe is stable in structure, not easy to be damaged and cracked, and has a low price. It can effectively reduce noise. It has been gradually applied in building wiring, household appliances, communication equipment, etc.

2. Impact resistance

1) The special structure of HDPE pipe makes it have high mechanical strength and high ring stiffness, and can withstand strong impacts more strongly than traditional pipes, such as areas with multiple earthquakes.

2), the low temperature resistance of HDPE pipe, strong ductility, not easy to be brittle, can resist the impact of extremely cold weather, such as northern China.

3. Wear resistance

The high polymer composition of HDPE pipe is the main reason for its high wear resistance. The wear resistance is even higher than that of most metals, and the self-lubrication is good. It is an ideal pipe.

Details

Application

1. Landscaping pipe network: Landscaping requires a large number of water pipes. PE water supply pipes are flexible and low-cost, which is the best choice;

2. Sewage discharge pipe: PE water supply pipe has unique corrosion resistance and is suitable for the discharge of industrial wastewater and sewage. It not only has a long life, but also has low cost and maintenance costs;

3. Mine mortar transportation: PE water supply pipes have high-strength compression resistance, wear resistance and corrosion resistance, and can be used for ore transportation and mud transportation for river dredging.

4. Agricultural irrigation pipes: PE water supply pipes have smooth inner walls, large flow capacity, and good impact resistance. They are ideal pipes for agricultural irrigation;

Certificate

Company Profile

High Mountain Pipe Industry is a high-tech enterprise integrating production and sales of sewage treatment equipment and municipal water supply and drainage pipelines. With a long-term vision and taking advantage of the background of Internet big data, we rely on our own production technology strength to continuously explore the transformation and upgrading strategies of traditional production enterprises, and become a new domestic "Internet + pipeline building material" production enterprise! The company integrates product development, production and sales.

The company takes "sunshine trading" as its corporate purpose; relying on a large number of production equipment, scientific production formula, staff team, and strong production force, it is committed to improving the quality of China's pipeline building materials, making prices more affordable, and making transactions more transparent.

FAQ

Q: Is the price on this page correct?

A: The listed prices are for reference only, please contact us directly for the latest prices.

Q: Is it possible to use the label or packaging I specified?

A: Yes. If necessary, we would like to use labels or packaging according to your requirements.

Q: Can you make special designs and logos on your products?

A: Yes, it is very easy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!