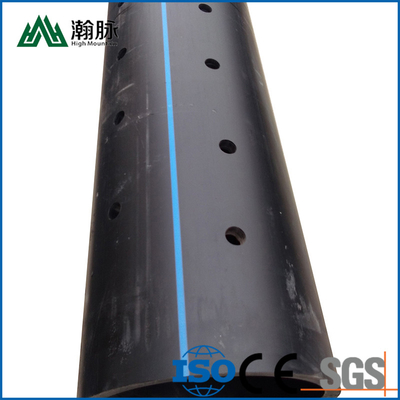

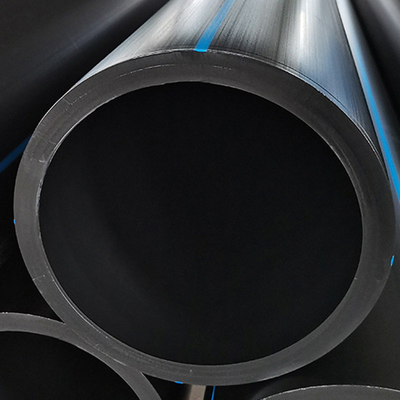

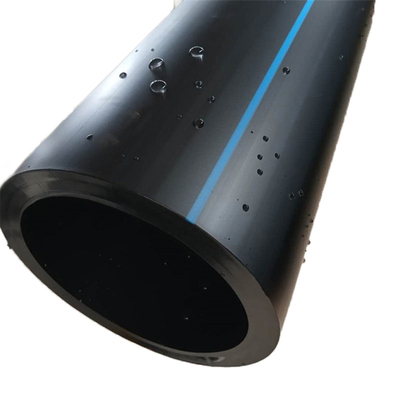

Customized Large Diameter 1100mm Thickness 6.6mm Hdpe 100 Black Water Supply Pipe

----------------------------------------

Basic Info.

PE water supply and drainage hot melt butt joint steps

1. Put in the PE pipe to be welded, fasten the fixture, and adjust the amount of misalignment

2. Put in the port milling cutter to correct the port plane until continuous chips are formed, take out the milling cutter and adjust it again to check the coaxiality

3. Put the preheated heating plate into the middle of the rack, and close the port for port heating

4. take out the heating plate after absorbing heat within the specified time

5. Quickly close the fixture, close the PE water supply pipe to be welded, and steadily increase the pressure

6. Keep the pressure until the interface part cools and reduce the pressure to zero, then loosen the clamp to take out the pipe and complete the welding.

Outer Diameter

DN (mm) |

SDR 9

PN20 |

SDR 11

PN16 |

SDR 13.6

PN12.5 |

SDR 17

PN10 |

SDR21

PN8 |

SDR26

PN6 |

Packing

Loaded into 40GP/Piece

6m or 12m per Piece |

| |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

Wall Thick Ness(mm) |

|

| 75 |

8.4 |

6.8 |

5.6 |

4.5 |

|

|

1085 |

| 90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

|

754 |

| 110 |

12.3 |

10 |

8.1 |

6.6 |

5.3 |

4.2 |

504 |

| 125 |

14 |

11.4 |

9.2 |

7.4 |

6 |

4.8 |

378 |

| 140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

304 |

| 160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

224 |

| 180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

182 |

| 200 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

143 |

| 225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

110 |

| 250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

90 |

| 280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

72 |

| 315 |

35.2 |

28.6 |

23.2 |

18.7 |

15 |

12.1 |

56 |

| 355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

42 |

| 400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

30 |

| 450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

25 |

| 500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

20 |

| 560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

16 |

| 630 |

70.3 |

57.2 |

46.3 |

37.4 |

30 |

24.1 |

12 |

| 710 |

|

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

9 |

| 800 |

|

72.7 |

58.8 |

47.4 |

38.1 |

30.6 |

6 |

| 900 |

|

81.8 |

66.2 |

53.3 |

42.9 |

34.4 |

6 |

| 1000 |

|

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

4 |

| 1200 |

|

|

88.2 |

67.9 |

57.2 |

45.9 |

|

| 1400 |

|

|

102.9 |

82.4 |

66.7 |

53.5 |

|

| 1500 |

|

|

110.2 |

88.2 |

71.4 |

57.6 |

|

| 1600 |

|

|

117.6 |

94.1 |

76.2 |

61.2 |

|

Advantage

1. High strength, excellent resistance to environmental stress cracking, and good creep resistance;

2. Good toughness and flexibility, strong adaptability to uneven foundation and dislocation, and can withstand harsh environments such as earthquakes and typhoons;

3. Has good weather resistance (including UV resistance) and long-term thermal stability;

4. Corrosion resistance, no need for anti-corrosion treatment, long service life;

Details

Application

Sewage discharge pipes

HDPE sewage treatment pipe refers to a system of pipes, canals and their ancillary facilities that collect and discharge sewage, waste water and rainwater. Including mains, branches and pipes leading to the treatment plant, whether built on the street or anywhere else, should be counted as drains as long as they are drains. HDPE chemical pipes have high chemical resistance to rings dissolved in civil and industrial wastewater.

Certificate

Company Profile

High Mountain Pipe Management Industry With 19 years of experience in R&D, production and sales of plastic pipe fittings, HDPE pipes are of good quality. In order to meet the actual needs of modern high-quality buildings and the design concept of environmental protection and silence, the company has introduced advanced production equipment and manufacturing technology, and has successively developed grooved ( HDPE) HDPE mute, HDPE grooved mute pipe, HDPE grooved drainage pipe compression drainage system and HDPE siphon drainage system series products. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. hdpe pipe factory adheres to the factory policy of "credibility, quality and management as the fundamental goal", with moderate price, dedicated service, and customer satisfaction as the purpose, abiding by contracts and keeping promises and famous all over the country.

FAQ

Q: How and when can I receive my goods after payment?

A: For small batch products, they will be delivered to you by international express (DHL, FedEx, TNT, etc.) or by air. It usually takes 3-5 days to receive the goods after delivery. For high-volume products, it is worthwhile to see the goods and deliver them. It takes several days to several weeks to reach the destination port, depending on the location of the port.

Q: Is the price on this page correct?

A: The listed prices are for reference only, please contact us directly for the latest prices.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!